Navigator V1 TLUD

The 'Navigator' TLUD is a '2 in 1' standalone stove and burner used with the optional 'Universal Pot Stand' (UPS - see the 'Permastove Kitchen' page for more details) for heavier pots or pans (or even a grill).

Materials

- 1m length of 304 1.6mm stainless exhaust tube

+ 2D laser cut 304 2.5mm cross piece

+ Optional (inverted) wok ring for Kadhai wok

+ deep oven tray

Tools

- small grinder eg.100mm (disc is 2.5mm thick)

- large grinder eg. 230mm (disc is 1.9mm thick)

Design

- 3 x 310mm tube sections

- 1 x 50mm tube section for length extender for optional UPS, raising the TLUD height to ~365mm (5 (oven tray) + 310 (main tube) + 50 (extender))-> 35mm below the stove top, which is flexible

for lighter pots or pans (no height drop) and heavy pots eg.a 13L full, 15L stainless stockpot, which lowered the height of the UPS by 20mm (the leg folds are a little flexible at the vertices)

but locks on and is stable. Tertiary air space will therefore be 15-35mm between the TLUD and the stovetop for a balanced amount of tertiary air and the rest will be above the stovetop up to the

bottom of the pot/pan/grill.

- 2 rows of primary air slots at base

- 1 row of secondary air slots eg.230mm above base (enough volume below for a range of feedstocks and burn times)

- 4 equidistant notches eg. 3mm x 3mm on top (for stable cross piece placement for pot stand)

All up, enough air flow for a super clean and smokeless burn - with biochar at the end!

PPE

- goggles

- respirator

- face shield

- gloves

- cotton clothing

Build

- set up the bush vice

- 3 vertical besser blocks

- towel

- rope

-secure 1m 5" exhaust tube

-cut off tube sections with large grinder (3 x 310mm and 1 x 50mm)

- grind the primary and secondary slots and 4 notches (if using a cross piece) with a small grinder

Can use a vice for cutting slots and notches/Vs or can be done on the ground (not as ergonomic) with one hand holding the tube and the other hand operating the small angle grinder

-2D laser cut multiple cross pieces if starting a business or producing multiple Navigator TLUDs

OR cut multiple Vs around the top circumference eg. 30mm deep for tertiary air

DONE

Operation

-fill the TLUD with fuel eg.wood pellets, rice husk pellets, bamboo, sticks etc. up to desired level to a maximum height of the secondary air slots

-add the cross piece (if available) if using TLUD in standalone mode OR place in position under UPS (plus tube extender) if using as a burner

-light the stove from the top eg. using 'firelighter gel' and a lit wooden skewer at one end

-wait until the top of the fuel layer is alight

-add the pot/pan/grill

-ready to run without adding any additional fuel during the burn

At the end of the burn:

-flame goes out

-remove the pot/pan/grill

-water added from top eg.watering can, for initial quench of biochar pellets until oven tray is half full (mind the steam)

-lift and remove the UPS and tube extender if needed

-lift the TLUD vertically eg. 20cm above the tray, with a C clamp

-use a stick to push out the biochar pellets into the water in the oven tray

-stir the biochar pellets into the water and there will then be a completed quench

-empty the oven tray into a bucket eg. a 20L stainless one, once the tray has cooled down then it will be ready for the next burn

DONE

After testing the 6" 'Chimney TLUD' I worked out the flame was too large - even with the wood pellets. I went down to a 5" 304 1.6mm stainless exhaust for a smaller flame cap.

I cut the sections off a 1m length of exhaust with a 230mm Metabo grinder - did the job though a pain in the arse to anchor while cutting, which I did with a few vertical besser blocks, towel and spiral rope fastening.

I cut primary (2 rows) and secondary (1 row) air slots with a 100mm small grinder, 7 around the circumference of the tube for each row.

I also tested this design with sticks, which burned for 25mins - enough for most camp food situations.

The wood pellets burned for an hour (with a half filled fuel chamber/chimney - repeated 3 times), with a fairly consistent size and stable flame the entire burn. More fuel could be added up to the level of the secondary air slots for a longer burn time.

I used a crosspiece from the Flat Permastove (2D laser cut off 2.5mm 304 stainless) as a pot stand which worked perfectly with 4 small equidistant notches (3mmx3mm) on the top to support the 2 pieces to provide a very stable and level pot stand. I added the wok ring for the Kadhai wok which could be a permanent addition for the pot stand as it also serves as a wind shield for a more stable flame.

After the burn, I poured on some water at the top with a watering can (with a lot of steam activation), lifted the TLUD with a C clamp (even too hot for welders gloves), poked the biochar pellets with a stick and they fell into the tray half filled with water and completely quenched. No warping of the tube, as predicted.

I'm hoping some TLUD punters might play around with the slot patterns and the tube length. Please get in touch with your results...

More testing needs to be done but overall a pretty well thought out design using less steel than all the other TLUDs I've built and should work well with most dry biomass feedstocks which will vary in burn time depending on the moisture content, feedstock type, feedstock particle size and volume of feedstock in the TLUD.

Total cost in AUD: 33 for the exhaust tube section, 5 for the cross-piece, 10 for the wok ring, nothing for the repurposed oven tray and 2 for the C clamp. The 2L billy, Kadhai wok, teapot billy, watering can and bucket are additional costs. All in all a well stocked outdoor/camp kitchen.

I should mention too that 1 TLUD could be used as a burner for a UPS for potable water and the rest for sanitation, 1 standalone TLUD for curry and tea and 1 standalone TLUD for brown rice.

They could all be run at the same time for convenience within a one and a half hour footprint.

The Fifth Burn

Just need to repeat it a couple more times and hopefully will be as good as 'Black Gold'.

Thin bamboo testing

The 10th burn

- standalone mode

- quarter filled with wood pellets

- 2L of water in the 2L billy boiling at 25m

- 41m burn time

- 100% Biochar recovery

Navigator V2 TLUD

I'm also going to have a crack on a smaller TLUD using 4" 304 exhaust tube using wood pellets as the main fuel source. I should mention here that the 1m lengths of exhaust should be considered for prototyping, small production runs and not mass production. Also, the high quality grade of 304 exhaust tube is probably overkill for wood pellets.

Advantages over V1

- less steel->lighter, smaller volume footprint, less iron ore etc. and lower C footprint

- cooler flame and more fuel efficient

- suitable for wood pellets (environmental feedstock too in small pieces, possibly mixed with wood pellets)

- similar UpDraft for UPS integration (but a little less in standalone mode)

- cheaper- can be integrated with a UPS with a tube extender eg.170mm

- Essentially, a portable TLUD for a UPS 'Docking station'

Specs

- Same mainframe as Navigator V1 TLUD

- Should also be OK for a 2L billy - not sure about the Kadhai wok (need to test for stability)

- Uses same 2D laser cut (2.5mm 304) cross piece in standalone mode (220 x 40)

- Maximum fuel volume and dims similar to the Permastove V4 which has been extensively and successfully tested.

- No patents or patents pending. This design is an adaptation for a grinder and steel tube of the main TLUD mainframe which is completely 'Open source'.

I've seen, sold, used, designed and built many different stoves over the years. This could be a cost-effective and 'Green' multi-biomass fuel stove (but need to follow fuel restrictions wherever you go eg. National Parks). So, depending on fuel restrictions, possibly no more ethanol, butane, propane, white fuels eg.Shellite, petrol, diesel, kerosene etc; no pressurised and single use gas canisters or pressurised fuels for mutli-fuel stoves, easy to operate, no electronics to potentially fail, solid state operation (no moving parts), 4 parts (tube, cross piece (2), C clamp/pliers), no maintenance, clean emissions (none or minimal smoke, depending on the moisture content of environmental feedstocks if used), high if not 100% biochar yields (Carbon negative), can be 'quenched' with water or soil, a little on the heavy side for alpining (plus there's the fuel access and the stove and fuel weight problem at higher altitudes), probably not suitable (or allowed in more regulated Countries) for indoor use, durable and modular stove that just might be a success in the future for many use case scenarios, especially in Australia. Can't wait to prototype it (disclaimer - it should work great based on previous testing of other designs - but it might not)!

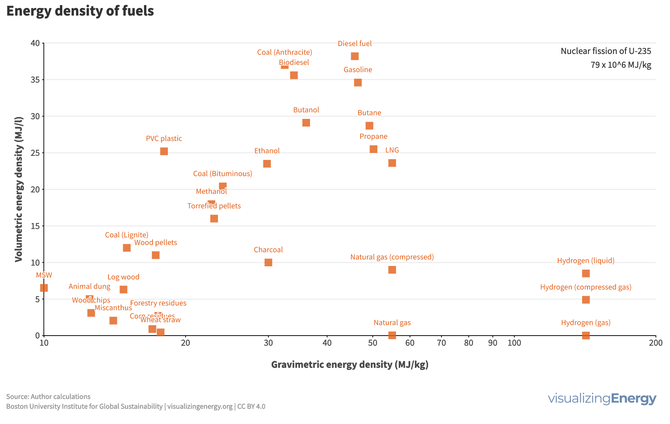

As you can see, wood pellets have a relatively low volumetric and gravimetric energy density compared to other liquid and compressed fuels. But - in most cases produced from sawdust - a 'waste' stream from sawmills, which may or may not use sustainable forestry practices eg.FSC certified. Safer handling too than most other fuels. May need to research your pellets. In Australia, it's an emerging fuel source with a small number of options for Australian produced, affordable and large bags eg.15kg. Balancing all this, get the wood pellets that are also closest to you for the smallest logistics C footprint.

Alternatively, if you're in it for the long haul and can access locally produced sawdust or rice husk, you might consider buying a small and electrically compatible pelletiser machine that can process sawdust or rice husk. Most of these are from China. Not sure about their reliability. Plus there is postage cost, dubious warranties and customer service issues. Can be expensive but over time possibly save you money if all the ducks line up and depending on how much pellet fuel you are consuming. Bags of pellets, produced by your pelletiser, could also be locally bartered or sold.

More information about clean stoves can be found here, with some great info under 'Publications'.

http://aprovecho.org/resources/

Permachar

Permachar