https://www.xprize.org/prizes/water

Biomass feedstock->Biochar->(1)Water treatment eg.gravity filtration, solar->Sanitation->Compost->Carbon removal/sink + Biomass feedstock growing in a Regenerative Agroforestry System (RAS) (Zone 2) with V swales and Zai pits->Biochar->(2)Inoculation in 100L stockpot->Carbon removal/sink + Zone 1 Growing systems eg.Microgreens, fabric pots->Food and medicine->Waste->Compost (+biochar/urine/humanure from sanitation above)->RAS->more Food and medicine + biomass feedstock growing->more biochar

= Carbon Removal for a Cascade of Uses (CRCU).

Applications of biochar bucket filtration system (based on the 'Permafilter' 2 x 20L plastic bucket prototype): general water filtration, and hypothesised brackish/fracking fluid contaminated water filtration eg.bore water, for potable water. There's also a bigger problem: sea level rise->saline intrusion of coastal freshwater aquifers->brackish water, which could be on a small island or along the coast of just about anywhere.

The biochar bucket filtration system could possibly be used for filtering out Total Dissolved Solids from pure seawater too. Need to test with simulated TDS levels in freshwater using swimming pool salt and a digital TDS meter for feedback. I'm also betting the 50L 'Stockpot TLUD Biochar System' (STBS) (more info on the TLUD web page above near the bottom of the page) will run a high temperature pyrolysis fire for massive surface/adsorption area of the biochar produced which should be perfect for the <15% 'Moisture Content' of thin bamboo feedstock for 'Activated biochar'. Just have to wait for Mayday to initiate testing.

It would be interesting to test different TLUDs, different feedstocks and different designed biochar filters.

It would be great if all the steel and it's components could be manufactured in Australia with 'Green Steel'. For eg., How many reserves of magnetite for Direct Reduced Iron (DRI) (suitable for 'Green steel' processing) exist in Oz? Is anyone manufacturing 50 litre stainless stockpots or 20 litre stainless buckets in Australia?

I'm predicting that most of the X-Prize applications will emerge from fairly well-funded operations eg.Universities, Start-Ups, Corporations etc. The solutions will be mostly complex, expensive and possibly over-engineered with too many supply chains and not appropriate for many remote locations without much/?any access to global supply chains/industrial materials/components and spare cash. The system proposed here is modular and scalable for multiple units. It will also use mostly off the shelf components (in Australia) that will be modified for the final design. Although I am prototyping with stainless steel tech, material substitutes need to be an option - however - I'm hoping to build a plastic-free system - microplastics are now everywhere in the oceans and even in the rainfall. The ol' plastic jerry can could be made of steel. I also aim to build a system without electrical components that may be hard to get and could fail. The Atmospheric Water Harvesting (AWH) systems on the market have too many parts that can break down, depend on an available supply of spare parts, use electronics, use electricity and cost too much - you're looking at AUD$2k for an average 15L/day system. This is also an interesting area of research that I am pursuing. Welcome to Vandana Shiva's 'Water Wars' and Carbon removal wars/competition. This can be done peacefully. Please - 'Give char a chance'!

Anyone want to join the team? Please get in touch on the 'Contact' form if you are interested and we can pool knowledge and skills.

REFERENCES

https://reneweconomy.com.au/why-magnetite-will-be-crucial-to-australias-green-steel-transition/

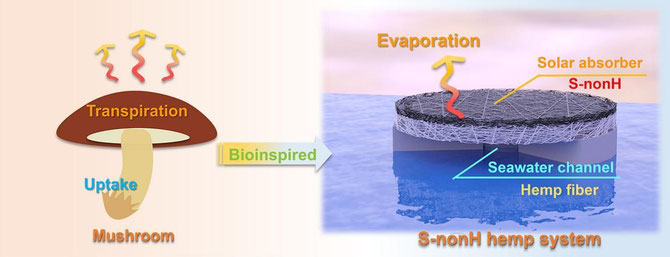

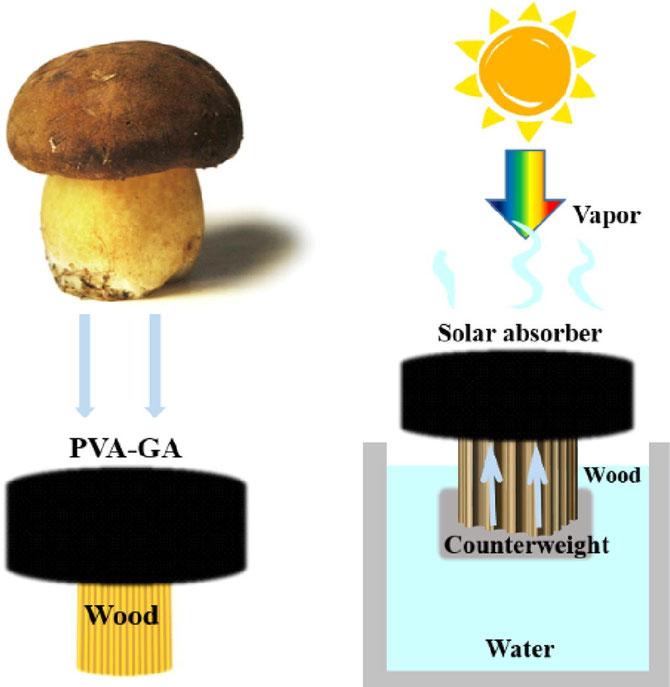

What I'm predicting is the biochar bucket filtration system will probably work well for brackish water but not for seawater. The concept is based on the way a mushroom naturally wicks water with stem capillaries and evaporates moisture at the top (biomimicry). In the above diagram, the design could possibly desalinate seawater too. The idea is a 3D printed vase could be made from ASA filament which exhibits high UV resistance and resistance to thermal degradation and is recyclable. The vase would be filled with finely milled biochar which would wick saline water from the base upwards to the top surface area subject to heat and sunlight. The biochar would also filter out some salt. There is literature claiming biochar can make a good solar absorber, though usually combined with other materials or chemicals such as polyethylene glycol (PEG) - but - PEG is made from fossil. I'm predicting bioplastic filaments, possibly incorporating biochar, will be made available in the future (if not already - needs more research).

From experience with wicking pots, finely milled biochar works well for wicking.

The dome at the top of the vase would be used for collecting evaporated water then trickling it down the sides for collection in a water trough. The dome would be made from clear acrylic. Like

polycarbonate, acrylic is a clear plastic with outstanding impact resilience that still offers excellent clarity. Acrylic has exceptionally high UV resistance too.

No moving parts or electronics that could fail. Could be perfect for remote areas eg.a coastal village, with a 3D printer, possibly in a regional centre, rather than importing the vase. Acrylic domes are a trickier tech, could be possibly imported - or something else could be used. I haven't had much luck with greenhouse plastic (plus it breaks down eventually and produces microplastics) but there could be something else I haven't found. Glass is the obvious alternative. Possibly in an upright trapezoidal pyramid made from 'Lion glass'. The water needs to be able to form large enough droplets to trickle down into a collector.

Or if it's all too hard, the ol' bucket gravity fed biochar filtration system with the biochar needing replacement more often as the salinity level increases. Needs testing.

Permachar

Permachar

Write a comment