I'm trying to simplify my business due to all these supply chain issues emerging around the world.

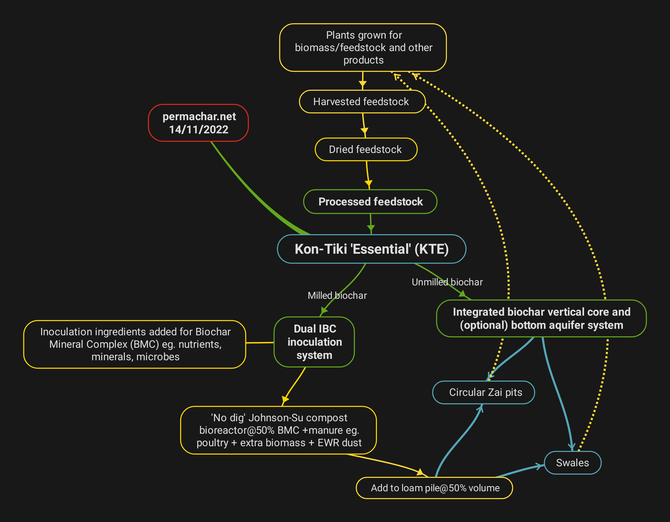

The Kon-Tiki 'Essential' (KTE) is an affordable, supply chain hardened biochar kiln with for Carbon-negative 'regenerative' food and medicine production along with hundreds of other applications.

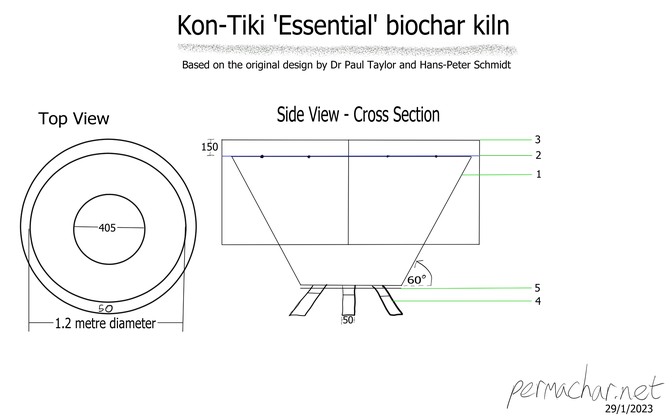

Tech specs for the Kon-Tiki 'Essential' biochar kiln

1. 1.2m rim diameter 3mm 'Redcor' HW350A inverse truncated cone (weathering and watertight) with flat bottom

2. 12mm cone reinforcement ring at cone rim with 50mm gap plus extra reinforcement at ground contact point during tipping/kiln emptying

3. 1.6mm 'Redcor' HW350A rolled 'quad heat shield' (weathering, 4 pieces for easy attachment & removal via pop riveted hooks) with 150mm height above the cone rim for safety, greater energy

conservation, higher temperatures for higher surface area and toroidal convection loops for cleaner pyrolysis

4. 3 galvanised screw-in legs (2" diameter, 250mm length) screwed into bottom welded 2" 45 degree galvanised bends for smoother logistics from A to B, especially with multiple units, stable

tipping to empty biochar after a burn and when not in use, adequate water drainage after rain along and inside the tipped cone

5. bottom heat shield, welded 12mm below the base with 12mm solid tube matrix and hollow thermocouple tube in between the cone bottom and heat shield, for greater energy conservation and thermal

observation

Photos of the KTE prototype

KTE as a biochar maker, firepit and outdoor sculpture - 3 in 1

Choosing a Kon-Tiki biochar kiln

There are many factors to consider when choosing the perfectly intregrated Kon-Tiki kiln for your needs. Water, agricultural resource input, tech/tools and their availability, skillsets, accessibility, cost and probably other factors too. There's always the 'Lu'au' pit but still faces similar constraints however this is probably the cheapest way to make small to medium batches of biochar but requires more labor, soil and is less ergonomic than the Kon-Tiki biochar kilns. No drain too. Could be an interesting option for Terra Preta making which I intend to test in the KTE. Ultimately, it depends on what you want to do with the biochar and how you integrate the biochar into your growing system(s) or whatever other applications you are using if for. Every design choice is imperfect but I believe the KTE will cover most bases for small to medium scale biochar research and development and provide versatile hardware for the 'Charista' well into the future with very high quality weathering 'Redcor' steel and continual improvement of the biochar firmware integration with other system hardware eg. Zai pits, swales etc.

If you are interested in building your own KTE or even starting a business, I am open to selling you my CADs at a reasonable price with free consulting to get you going. Please reach out on the 'Contact' page and maybe we can solve a problem together.

A regenerative semi-arid growing system

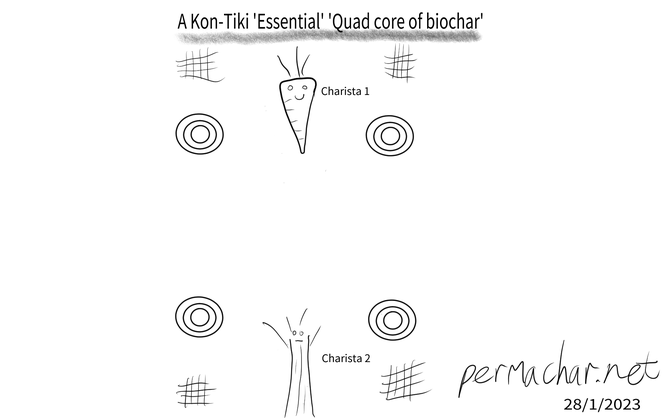

A 'Quad core of biochar'

A diagram of 4 KTEs in a square for easy access and safe operation plus upward scalability from using just one 1.2m Kon-Tiki biochar kiln. The kilns can be operated at the same time or different times. Basically, a multi-core CPU that can scale 1 to 4 cores at a time for your biochar operation! A simplified system with no drain, pump and IBC for each unit, instead utilising a scalable dual IBC inoculation system that should be able to cover many microbe inoculation scenarios.

2 or 4 KTEs?

I'm selling 2 or 4 units.

2 KTE's (a 'Dual core of biochar') is a great entry point for 1 Charista if the feedstock is well prepared.

4 KTE's (a 'Quad core of biochar') would be perfect for 2 Charistas, running 2 kilns per Charista if the feedstock is well prepared. By my calculation, it's the best entry level price point

for medium-scale biochar production for a small settlement/biochar product business.

Please contact me for a quote.

For eg. in a product business, the following products could be made:

-unmilled biochar

-BMC, for adding to soil or possibly direct seeding/planting

-pelletised BMC and Asparagopsis for livestock feed, chicken feed, dog feed, cat feed etc.

-pelletised BMC (eg.biochar and kelp) for perlite replacement in seedling and hydroponic systems

-BMC compost eg.with poultry manure, for agriculture, viticulture, agroforestry, horticulture etc.

In permaculture inspired 'ecovillages' with better access to resources, 4 KTEs at the centre of the village could be used to build out the growing systems with BMC and biochar possibly used in

some building materials eg.charcrete, hempcharcrete etc. Construction of biochar water filtration systems is possible too. The list goes on...

4 KTE's is great value considering how expensive and complicated the larger kilns currently are which also require maintenance. There's no maintenance for the KTE as it is weatherproofed with the

only moving parts being the quad heat shield which is very easy for most people to add and subtract to the kiln and the kiln itself when it's tipped over to empty the biochar and remaining

water.

A 4 unit order is also best from a laser cutting and logistics point of view. I'm open to larger orders too but it depends on the workload of the fabricator for wait times before product

delivery. Maybe we've almost beaten COVID-19 in some countries but large scale logistics in Australia is tight and increasingly expensive. Future upgrades of renewable energy for engines

eg.Diesel to Hydrogen, Hydrogen, Hydrogen/Electric or Electric and Carbon neutral payloads will hopefully drive logistics costs down. One day logistics may even be Carbon negative with biochar

solid state batteries and Carbon based perovskite PV panels.

Any number of 'Lu'au' biochar pits could work in a small village too with no access to steel fabrication.

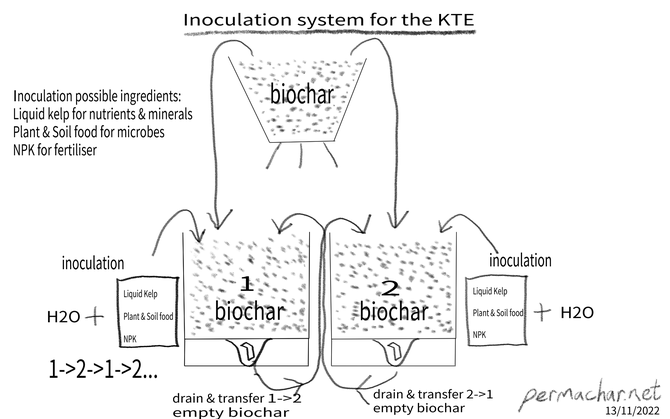

Inoculation system for the KTE

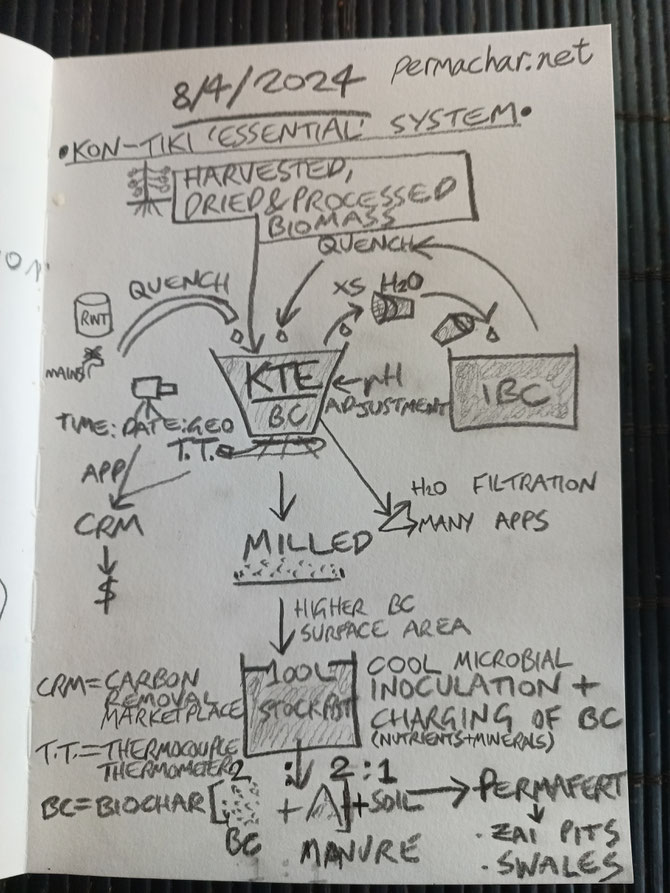

In the above diagram, a biochar mineral complex (BMC) is produced by inoculating the biochar.

This approach solves the problem of 'hot charging' microbes in some cases but who knows how many use cases, some which will and some which won't survive the heat (depending on the microbes, eg.those found in cow urine seems to survive) in a recycling bottom quench drain system. However microbes can be sprayed onto biochar or the biochar can be co-composted for inoculation with Indigenous Micro-Organisms (IMOs)/added Non-Indigenous micro-organisms.

In this integrated design it is pump-free/drain-free (though unfortunately not plastic-free) and all of the inoculation using 'cold charging' can be done at the same time in one step with nutrient, mineral, microbe and fertiliser conservation and product savings.

The inoculation fluid from the first IBC is reclaimed and reused after inoculation by draining it from the first IBC into a 20 litre ss bucket and transferring it to a second IBC filled with biochar and vice versa. A top up of water and inoculation ingredients will be needed for every new inoculation. An additional benefit of reusing the inoculation water is the microbial populations will grow over time - unless of course you want a one-off inoculation, then you would have to clean the IBCs in between every inoculation with more work, more water and more IBC downtime - not what I would want to do

If more IBC capacity is needed then pairs of IBCs can be added to the system with geometrical scalabiity (including more KTEs as needed).

Some other variables to consider are:

-the time needed for 'effective' inoculation

-using unmilled/milled biochar for the inoculation

*unmilled will have less surface area for inoculation than milled biochar but won't potentially 'clog up' the internal mesh drain at the tap

-since every ingredient of inoculation has different dilution rates, an ideal ratio of the ingredients would need to be researched for possibly a single uniform liquid input eg.customised for a specific plant monoculture (or take an average result for a plant guild or polyculture) that could be premixed before adding at a single dilution rate to a measured amount of water added to the level of the top of the biochar in the IBC.

The inoculated biochar, if unmilled, could then be milled if needed for Permafert middens and other ingredients could be added to the middens eg. compost, manure, fungi, rock dust, earthworms, soldier fly larvae etc.

Alternatively, the midden step could be bypassed and 'no dig' 'Johnson-Su' compost bioreactors (possibly modded) could co-compost the BMC eg.50% with manure eg. poultry, with additional biomass if needed, then added directly to loam piles for permafert ready to go for swales or Zai pits (see latest RAS notes page) or tilled into conventional crop rows or something else.

The future of the KTE

The eventual goal is to make Kon-Tiki biochar kilns all around the country. I believe the key to success will be installing roughly USD20k fibre optic 1000W 2D laser cutter (as far as I know there are no Oz manufactured laser cutters), with possible Government subsidies, at small to medium sized fabricators in agricultural regional towns, possibly an industrial area in some cases. This would be good for making other machinery and parts too.

Note that StyleCNC offers spare parts for their laser cutters and are leaders in their field. Note that if it is assessed that the supply chain risk is too great for imported laser cutters, the sheet metal can also be cut with a plasma cutter (less parts but probably still imported) but will take more time, less energy efficient, less accurate eg.possible rough edges, which depends on the tech and cutter, and a plasma cutting skill set but affordable to many more fabricators. For eg, you could spend AUD$800 at Bunnings to get a plasma cutter - but would still need access to the other equipment eg. roller, welding gear, or use multiple fabricators which is less efficient.

The laser cutters could probably be powered from a standalone power bank with solar PV panels either ground mounted or on top of the workshop roof.

Here's a couple of links for further research:

Decarbon Venture: https://au.decarbonventure.com/?autoRedirect=0

StyleCNC: https://www.stylecnc.com/fiber-laser-cutting-machine/fiber-laser-cutter.html

The KTE opens up the small to medium-scale biochar market for more punters wanting to enter the Biochar Revolution and produce the most future proof material on the Planet!

Carbon removal credits for the KTE

There's also the possibility of generating Carbon removal credits for the KTE (or other Kon-Tiki kilns) either via an established Carbon Removal Marketplace (CRM) such as puro.earth or with a new open source CRM product specific to the Kon-Tiki biochar kiln. After a year of thinking about it, I found out that Carbon4Good had written an app called 'The Biochar App' which is not yet available on the Google Play store. So, I've come up with an alternative idea which could also feed into 'The Biochar App' while it's still at beta level as I don't have the funds to put together a team of software engineers and developers. So, here goes:

3FA for Carbon Removal Marketplace (CRM) MRV transparency and C removal credit purchase/ investment confidence

- photos, with time:date: geolocation (using purchased 'Timestamp Camera' app for about $7)

- first layer of burn (unique feedstock pattern)

- finishing layer of burn (unique feedstock pattern)

- after a quench (no good - Biochar floats to the top obscuring what's beneath)

- kiln tipped over after quench with Biochar visible (unique biochar pattern)

- sensors, with a RuuviTag Pro '3 in 1' (IP67, Bluetooth (BLE), open source code, 1-2 year battery which can be easily user replaced, AUD$73 + postage) ruuvi.com

- temperature (unique per burn)

- air humidity (unique per burn)

- movement (not needed)

+ QR code scanned on the K-T kiln (linked to a registry) used for the burn

**Tools**

Smartphone with an internet connection (which could be offline during a burn), a RuuviTag Pro '3 in 1' IP67 tag and a Kon-Tiki kiln.

**Auditing**

The system/app auditor should be able to recognize that a unique burn has been done producing an approximated volume of Biochar from a registered kiln with a specific kiln volume at a

specific location.

Who could be bothered trying to outsmart that?

**Bags with QR code idea in 'The Biochar app'**

Do specific biochar volumes produced after a burn or burns need to be measured (via bags) or is an approximation of biochar from a kiln good enough? Approximate biochar volume yield from a

burn is 45% so the volume of biochar from a burn can be calculated if the volume of the kiln is known. At the place of kiln fabrication, approved designs with an associated volume could be

built then QR code tagged for a kiln registry with the customer's details. Standard kiln operation/'software' (which could take some local training) would be critical for a reliable and

repeatable volume yield approximation. Registering individual kilns rather than projects would be a more streamlined process for individual Charistas. Bag supply, ideally Carbon neutral

eg.hemp, could be an issue for some locations too.

As long as the Biochar is made and C removed, I believe where it goes and what is done with it is irrelevant (though interesting).

For eg., with my modded KTE system (below) for local Biochar production and application, bagging the Biochar would impede the workflow of transferring the Biochar via wheelbarrow to the site

of application for milling, Inoculation, Permafert middens and application to swales and Zai pits.

There is one advantage bags have which I must concede on - moving the biochar around for retail distribution for product businesses, which may or may not be relevant for a given place or scenario.

**Conclusion**

After a large amount of research, I feel I can confidently say what is not needed: No video, no thermal/IR, no thermocouple thermometers, no PC software and no IoT (that needs routers or is

expensive with a Sim card eg. UbiBot GS1 - AL4G1RS).

***

Something you've gotta watch for the Xprize competition. Go Kenya!

https://m.youtube.com/watch?v=huqLMHRNIVA&t

NOTES

Variables

- feedstock

- species, subspecies

- size eg.300mm length limb wood, diameter eg.6-8cm

- Moisture Content (MC) of feedstock eg.15% or less

- outside temperature, rainfall and relative humidity during burn

- kiln design (eg.Kon-Tiki 'Essential')

- kiln operation (standard operating procedure - see manual below)

- Heat shield (HS) (usually not used in Luau pits)

- eg. 1mm galvanised steel or 1.6mm HW350 'Weathering' steel

Experimental KTE system

Features

- Food and medicine for People and Planet with a broken climate system - this idea is a 'Sustainable Adaptation' option...variations on the theme are out there - this one is my pick for 2024

- suitable for small-scale pot (fabric from hemp or recycled plastic) trials (Zone 1) or Agroforestry/'Food Forest' pits and swales (Zone 2+)

- pump free system

- could be used standalone or with an integrated app and CRM (as described above)

- water conservation with water reuse. After quench and pH adjustment, a 20L stainless bucket with stainless mesh on top can be used for easy water removal without the biochar. The water is then bucketed into an IBC. For the next burn, some of this 'smoke water' could be reused in the quench. Probably a better use of the 'smoke water' is to irrigate seedlings (promotes growth).

- higher surface area after milling for higher adsorption of microbes, nutrients and minerals on the biochar surface

- cool microbial inoculation which will increase survival rate of the microbes

- easy to measure quantities of microbes (eg.Popul8), nutrients and minerals (eg.liquid sea kelp, rock dust etc.) in the 100L stainless stockpot eg.fill up stockpot to 80L mark with biochar, calculate volumes of additional ingredients per litre of biochar then add and stir in. If adding microbes, I'd give it a couple of days. No products are wasted.

- multiple stockpot units could be used for larger quantities and less down time during inoculation and charging. Alternatively, 200L PE barrels eg.pickle (top screw-in lid), ethanol (cut longitudinally in half - I will also use one of these, leftover from my Permachar Kitchen Garden)

- easy handling of the stockpot (more difficult with barrels plus more plastic and even more difficult with IBCs and more plastic though can be done with smaller volumes and a bit of muscle - better emptied with 2 people)

- easy to clean stockpot between batches of inoculation and charging

- 40% biochar in the Permafert - roughly the sweet spot for biochar application in agriculture and horticulture though needs more field testing. This ratio can be played with depending on what soil is available and what plants are grown.

- the advantage of adding some soil (20%) is local microbiology/'Soil food web' and clay. It also bulks out the mix and is closer to Terra Preta than a soil-free system such as 'Compochar' which is more suitable for a continuous pyrolysis kiln system and very poor soils. I've come across a couple of operations that are using 1:1 biochar:manure for 'fertiliser' successfully though I'm unsure what ratio of the 'fertiliser' they are adding to soil, which will probably vary.

- As per usual, the Permafert will be mixed in a midden then applied to Zai pits and swales

Kon-Tiki 'Essential' biochar kiln manual

Ordering some KTEs

Please send me a message via the 'Contact' page and we can discuss what the best way is to move forward.

Permachar

Permachar