The integrated system should fit on a standard 1200x1200 pallet

- Significantly lower power output system than the PP30 Power Pallet or 1kW free piston Stirling engine.

-

Runs independent of the weather, day/night

- Could use a small pelletiser to produce wood/rice husk pellets from a small-scale regenerative agroforestry/rice farming system

-

The by-product of pyrolysis (the process used to burn the pellets) is biochar for C Removal in a Cascade of Uses (CRCU) eg.water filtration->regen agroforestry or rice growing->more feedstock for pellets

-

The biochar could be used to generate CORCs via puro.earth or C sink credits via carbonfuture.earth or even potentially Carbon4Good ...get paid to produce electricity and pay off the system!

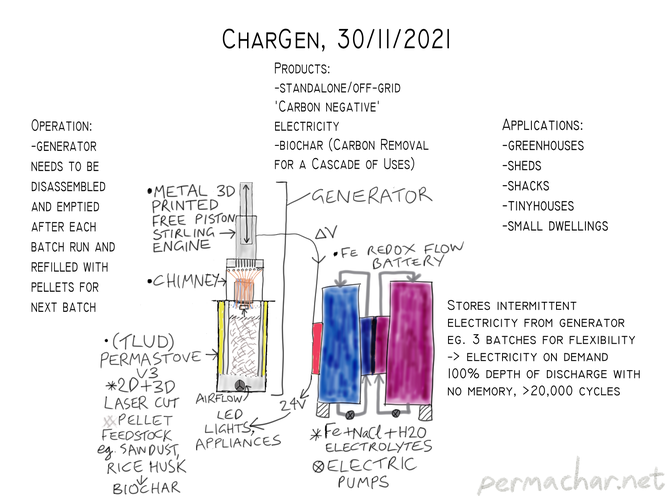

- TLUD tech for batch mode eg.Permastove Kitchen. Three batches for one full battery charge for added flexibility and headroom.

- An 'external combustion' Stirling engine eg.Thermo Acoustic Stirling Engine (TASE), 3D printed metal, variable Voltage output, quiet (good for urban settings)->electricity->charges battery

-

Easy removal of the Stirling engine eg.sitting on a 'Universal Pot Stand' (UPS) for access to the 'Permastove Burner' reactor. Top loaded pellets for a batch then after a batch has cycled, easy removal of the biochar via lifting the reactor out of the TLUD and tipping out the biochar. Refill with pellets for the next batch.

-

The ability to pyrolyse a large range of pellet moisture contents (MC) eg.ideally 15% or less but possible for higher MC

- Safe

- Reliable

-

Lightweight

-

Rugged

-

Durable

-

Reusable/recyclable

-

Green chemistry: Fe redox flow system, such as that used by ESS, with Iron, water and salt (Chloride ions) electrolyte. ESS does not offer a residential battery at this stage however that may change in the future. Alternatively, a saltwater redox battery chemistry could be used.

- Power drawn from the battery for consumption after being charged from the generator

-

Power on demand 24/7

- Generator coupling to the battery with the ?Victron Multiplus

-

100% depth of discharge so electrolyte memory/capacity fade not an issue. This is perfect for the variable Voltage output of the generator.

- Biochar electrodes (anode + cathode), possibly made from kelp or bamboo

-

High numbers of charging cycles eg >20,000

- Safe

- Reliable

-

Lightweight

-

Rugged

-

Durable

-

Reusable/recyclable

The Microgen 'BioGen' will have 1kW-2.4kW max power output models in 2022 or even the BioGS-1.0 (more awesome but expensive (20k Euros) and only 10% biochar yield (downdraft tech) with room for improvement. Uses the same 1kW Stirling engine as the BioGen so could be a nice engine to experiment with for a TLUD system but too expensive for my design (8,000 Euros).

What I'm thinking is that a TLUD batch system will have a higher biochar yield than a continuous downdraft system but would need to be coupled with a battery to utilise all the power produced. I can't see a reason why the BioGS-1.0 would need a battery as it can provide power on demand.

In my case, I would need SA Power networks approval if connecting a BioGS-1.0 (which I can't afford) to the grid for when the sun aint shining as I have a grid-connected PV system with no battery! If I was building a new energy system, I would skip the PVs and shoddy Li ion battery chemistry and go off-grid for C negative bioenergy with the CharGen and use 24V lighting and appliances. I can access sustainable feedstock/sawdust for wood pellets (pelletisers are available from alibaba and possibly elsewhere too). This C negative tech could be a niche though - to be sustainable with a low logistics C footprint it would need to be deployed near sustainable forestry (?regen agroforestry) sawmills (not much rice husk in Oz).

THE GRID

As far as the emerging grid goes, think inefficient synchrons (one in use and one for backup in SA for a grid that wasn't designed for renewable energy), slow rollout of inverter firmware updates (for Fronius and possibly other inverters), tiny Feed-In Tariffs if you jumped on the PV bandwagon late (that will probably never pay off your PV system), home solar shutdowns due to excess renewable energy not yet used to produce Green Hydrogen for transport (which ideally would be made onboard anyway)...but I guess some if not all of this will change in the future...

ADDITIONAL DESIGN NOTES

I was thinking using an oil drum TLUD that I designed 11 years ago but after watching this video, I think the Permastove V3 (see TLUD page) which is much smaller, more efficient and easier to fabricate (4 off a standard sheet) coupled with a Stirling engine with variable Voltage (DC) output would be perfect for the job:

https://www.youtube.com/watch?v=zL8oCafwF_E

With the above system, they were able to get 16V so with an efficient TLUD such as the Permastove V3 and a more refined Stirling engine with integrated DC output, a higher Voltage output should be achievable which might be perfect for charging a small-scale Fe redox flow or saltwater battery. My only concern here is whether a redox flow battery can be charged with variable voltage which would be ideal. Otherwise, if the Stirling engine can output a standard voltage, it should be easier to couple to the battery. A Victron Multiplus might be able to handle variable voltage but I need to research it. The pumps in the battery could be directly powered from the Stirling engine. Since the Permastove V3 is insulated, the fire will be hot (which may increase the rate of power production) and may not need a fan for forced air (FA). As I found with the Permastove V4, forced air made the flame too large when pyrolysing wood pellets. Circular holes all around the base of the Permastove V3 or small horizontal chimney for natural draft (ND) may be all that's needed however with the larger air space in the stove, a fan might get a cleaner more efficient result. It's tempting to use the Permastove V4 as the fire source but I want the larger reactor capacity of V3 which means a longer run time for charging for a larger capacity battery and besides, more biochar will be produced per batch.

Try 'Google Images' search for 'TLUD', 'Stirling engine', 'iron redox flow battery', 'saltwater battery'. There are many possible configurations!

APPLICATIONS

Greenhouses, sheds/workshops, shacks, tiny houses, small dwellings

As stated earlier, the battery could be charged with a variable voltage from the Stirling engine which would enable faster charging and be more energy efficient! Why more energy efficient? The heat energy from the TLUD will vary during the pyrolysis of the pellets (increasing then decreasing) and also vary with different pellet feedstocks and moisture contents so in order to maximise the heat energy output conversion to electricity, the Stirling engine would need to be able to scale up and scale down (headroom) with the changes in heat energy across the heat exchanger circular fins which would capture as much heat energy as possible and provide a variable voltage output. Given that a Stirling engine design I saw on YouTube can run on 3 tea light candles, the thermal energy from the TLUD could heat a pretty robust and low to mid powered Stirling engine. Maybe not 1kW or more which is what Microgen are using in the BioGen series. It would have to be R&D'ed to find the perfect balance between manual operation, heat energy, electricity production and storage.

Note also that a process to remove Chloride ions from NaCl is needed for the battery chemistry. Na is not needed.

SALTWATER BATTERIES

An even simpler battery chemistry could be used instead of an all-Iron redox flow battery chemistry: saltwater. There are various designs for this but one got my attention from Greenrock though the manufacturing looks fairly high-tech. Saltwater batteries seem to have similar safety and environmental advantages to the Narayan battery chemistry but without needing food grade Iron and there are no moving parts eg.pumps. If manufacturing was more inland, salt from Ozzie salt pans could be used and bamboo for the biochar electrodes. If on the coast, seawater could be used as the electrolyte, or possibly the salty brine from a desalination plant, and kelp for the biochar electrodes (with many species having higher surface area than most if not all bamboos but I suggest you fact check that one).

CONCLUSIONS

So, a TLUD with a free piston Stirling engine and saltwater battery would be my current combination pick as a small-scale alternative to solar and storage and the dark horse, being the Belgian solar Hydrogen panel that still needs more testing and may never be commercialised but sounds very promising for semi-arid, arid and possibly hyper-arid regions if there is enough atmospheric water vapour to drive it. Who knows what's out there being developed that could crack the code of sustainable small-scale energy production? Maybe it already has been cracked...but ultimately there will be many different greentech solutions for different locations with unique resource, manufacturing and logistics constraints.

REFERENCES

- PP30 Power pallet: https://www.allpowerlabs.com/pp30-power-pallet

- Microgen 'Biogen': https://www.microgen-engine.com/buy-engage/

- BioGS-1.0: https://www.kiratechnology.com/en-us/our-product/

- Awesome but not yet commercialised: https://hydrogen-central.com/belgian-researchers-solar-panel-produces-hydrogen/

- ESS Fe redox flow explainer video: https://www.youtube.com/watch?v=HmtI8Wat7rY

- Fe redox flow: https://essinc.com/iron-flow-chemistry/

- All-Iron redox flow battery: https://dornsife.usc.edu/labs/narayan/all-iron-redox-flow-battery/

- A saltwater battery: https://www.bluesky-energy.eu/en/saltwater_battery/

- DIY saltwater battery: https://www.aquionenergy.com/technology/aqueous-hybrid-ion-ahi/

Permachar

Permachar