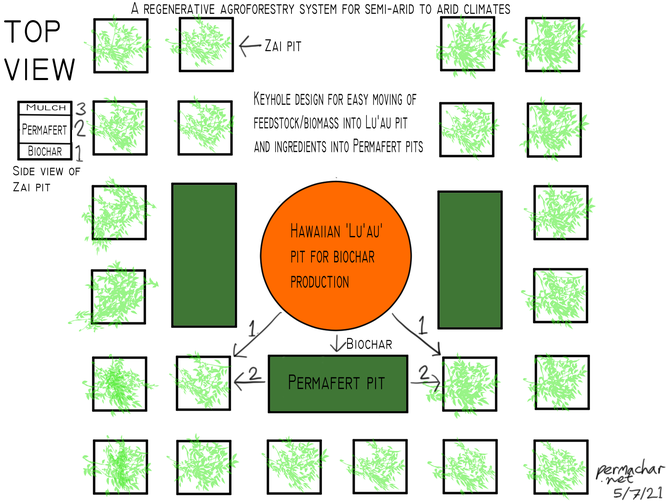

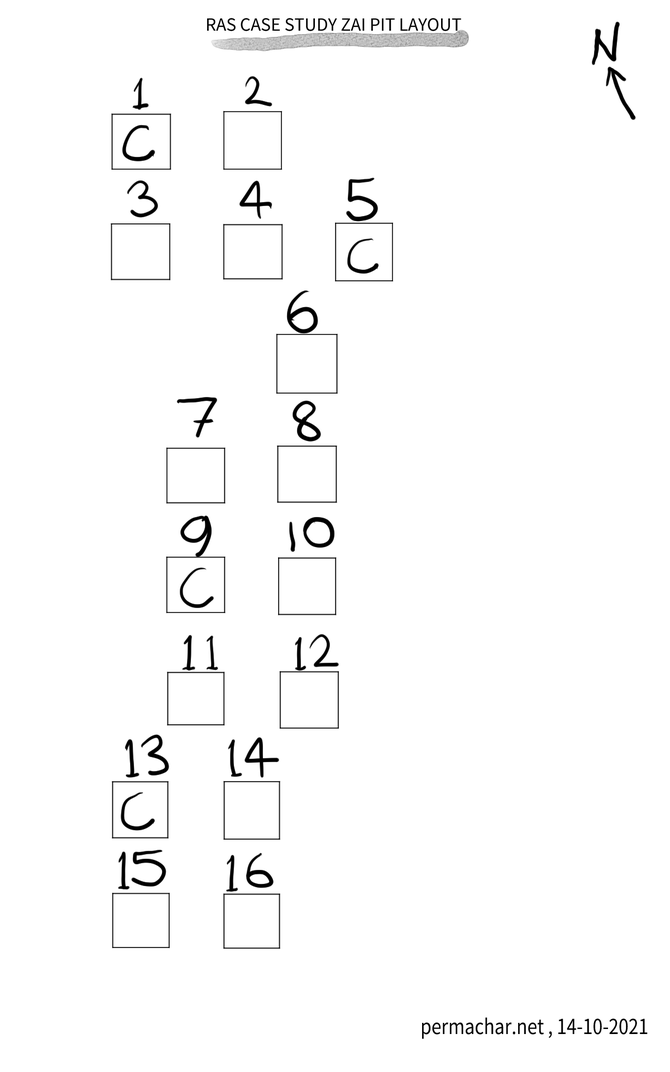

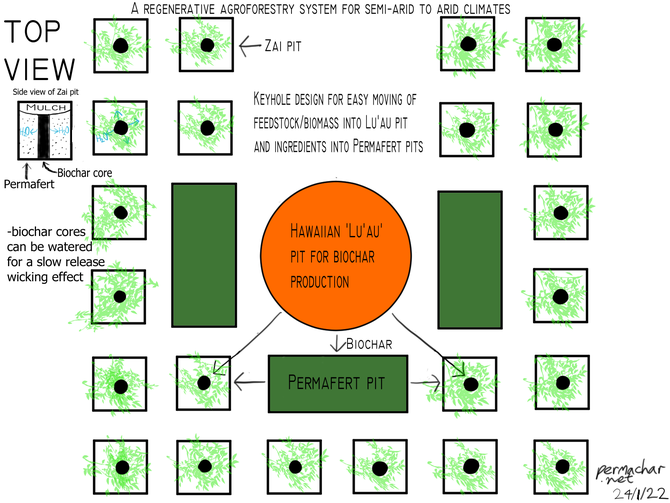

There are many possible configurations for this pit layout depending on where the water source for irrigation is (if irrigation is available), where the biochar feedstock is, where the Permafert ingredients are and different Permafert production tech eg. middens, pallet systems, pits. Separate Permafert pits are shown in the above diagram or possibly in-pit production used by most Zai pit farmers. Another option could be making some or all of the pits into 'Pyramid kiln' shapes (see 'Resources' page) and making biochar in-pit. Personally, I prefer a separate Lu'au pit or Kon-Tiki kiln eg.Rolls, as these conical structures are cleaner burning than 'Pyramid' shapes and allow quality and quantity control for building the aquifers in the Zai pits and making the Permafert in separate structures.

In terms of tools, all you really need is to cut 8 short stakes eg.thin bamboo, with a saw, and make a set square and pit depth measuring stick. I'm digging 900x900x350mm pits so I made a 900mm x 900mm set square from some old PVC electrical conduit pipe and a 350mm measuring stick for measuring pit depth. A long handled hoe eg.A $65 Cyclone long handled burr hoe (Oz produced with a lifetime guarantee), for breaking the soil (need to screw into the handle at the base of the head) and a $15 square faced shovel for shifting the soil. I used the shovel for the water catching mounds/berms around the pit. So, after staking out the pits, 2 at a time, using the set square and 8 short stakes, the digging begins. The shifted soil can be placed around the North and South edges of the pits, similar to swales, for larger scale operations. Since this is a small-scale exercise, I wanted to maximise the number of berms so I added 3 berms to each pit with one side for access, like a keyhole. The berm positions were sculpted (after rain) with the shovel, with some soil shifting, back of the shovel pounding and some hand pounding for the pit corners using my fists. There is enough space in between the pits for walking between and managing them, using mostly outer access points. All the berms are shared by more than one pit. The berms will increase the water catchment/harvesting in the pits with excess water soaked up in the biochar aquifer for wicking into the Permafert layer. The berms also provide some wind protection for the plants. Eventually deeper roots for some plants (annual/perennial) may even establish themselves within the aquifers or even deeper or lateral to the pit structure itself.

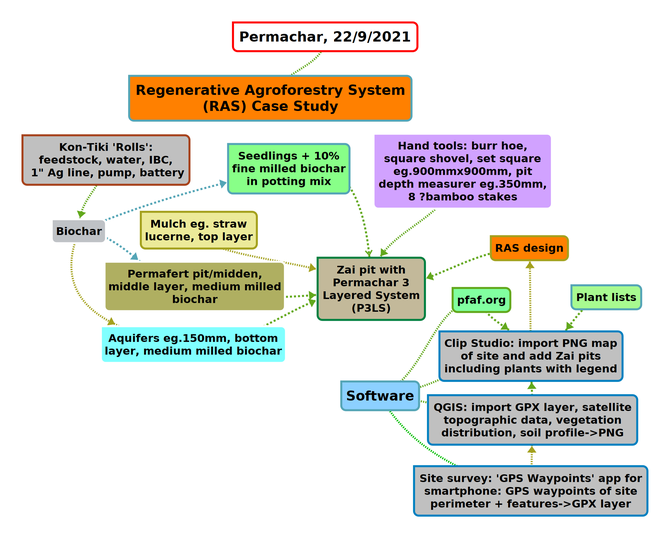

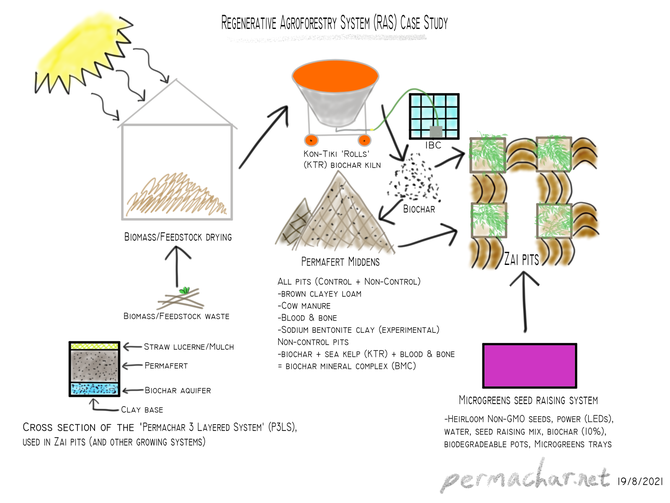

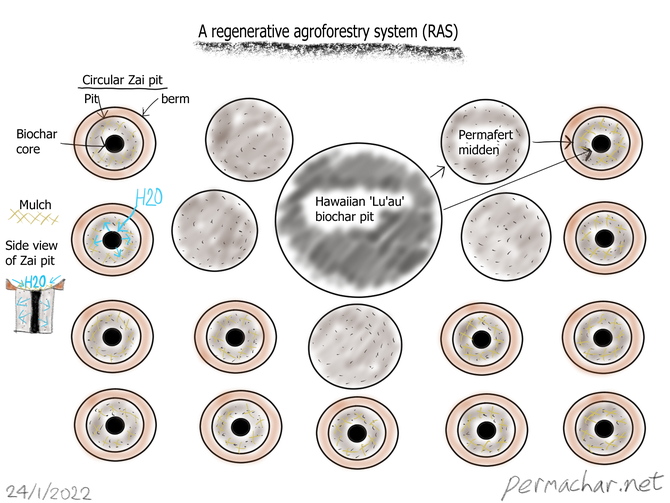

The Zai pit structure shown in the diagram is based on what I was able to test in pots, the Permachar Kitchen Garden (PKG), The Permafert Swale (TPS) and Permachar Wicking Module (PWM). I call it the 'Permachar 3 Layered System' (P3LS). Kind of looks like a multi-layered Carbon-based solar (PV) cell. The hope is the pits, like PV cells, will become 'greener' and more efficient over time. Though not purely scientific, I have tested these systems with different plants over months to years and they seem to work very well most of the time. I'm prepared to do a '3 sisters' plant guild trial using this pit structure on the Zai pits I am working on as I think with climate change, the Mediterranean climate in which I live, defined as semi-arid (500-800mm rainfall, aridity index between 0.2-0.5), due to a decreasing 'aridity index' (see the file download at the bottom of the page) will eventually transition to a more arid climate, like the RIverland, where the '3 sisters' should grow well but maybe they will grow well in the current climate? This trial may be a useful bioindicator for future trials/plantings with the future possibility of developing a network of RAS bioindicator sites throughout drylands ;)

I should mention too that while there is good rainfall around many parts of Oz, it's a good time to be digging pits, buying seeds, germinating them and growing seedlings for the Spring and making biochar in between the rain as there is less wind compared to Spring. It's also the off season for bushfires so the time is right to make biochar. Another thing is you can half-dig the pits with a square faced shovel while the soil is wet and when you get to the dry stuff underneath, stop digging and wait for more rain. After the rain, the second half of the pit is moist and easier to dig using a Cyclone burr hoe. I'm pretty stoked as I found red clay at 200mm depth which should be perfect for lining the bottom of the pits as it will buffer excess water beneath the biochar aquifer in times of heavy rainfall. In drier periods, the biochar (medium milling) will hold water and wick it to the Permafert as needed. Biochar has a higher water holding capacity (WHC) than sphagnum moss!

I am using existing trees for wind protection and have good access to North,Northwest, West sunlight. If there are no trees around, I would suggest planting species of the Acacia genus around the edge of the pit matrix, maybe in every second pit to provide enough space for tree canopy. These will fix nitrogen in the Permafert (or even reused soil from the pit), provide flowers for pollinators and birds (and for aesthetics), provide wind protection for the veggies and herbs in the middle of the matrix. Some species are good for coppicing for biomass/feedstock to make more biochar (charcoal, but with a different thermal profile of the charcoal you can cook with and loads more surface area) for more Zai pits in the future - a 'permanent agriculture'? Some species produce edible wattle seed and even edible flowers. Carbon drawdown is a plus too. Here's a good starting point for research: http://worldwidewattle.com/speciesgallery/home.php

I've drilled down to one species that I want to try growing which should be suitable for my location and functions: Acacia saligna (300-700mm rainfall), which is fast growing and can be coppiced for biochar production - which is a relatively new area of research.

I have sited the pits close to my Kon-Tiki 'Rolls' kiln (with nearby feedstock for biochar and a biochar heap between the kiln and the pits), 2 point water sources and nearby Permafert middens, which I may abandon and try Permafert pits instead for the trial/case study. I'll germinate the maize, beans and squash in August and plant in September. I'm also going to plant some pumpkins and zucchini too Acacia saligna in smaller pits around the edge of the pits.

I imagine that the Zai pits will have their greatest benefit in semi-arid to arid climate zones but should not be discounted in more favourable and wetter climate zones - they should still work though water-saving may not be their obvious benefit/feature. In very wet soils the pits probably won't be as effective and could even prevent successful growing of some plants due to 'wet feet'.

Could this be a solar, Carbon, Zai pit, permaculture, regen agroforestry and hybrid software revolution? In the future, it may be possible to integrate software and Carbon offsets and removal eg.regenfarmer.com using the Zai pit/biochar regen agroforestry system. This could significantly increase the income for farmers and help the planet decarbonise/recarbonise!! For eg., you could work out how much Carbon is sequestered/stored in one Zai pit and multiply that number by the number of similarly built pits for accounting purposes...voila...'geometrical replication' of pits for Carbon drawdown and a growing population on a rapidly desertifying planet with a green Covid-19 recovery. But, would this be yet another form of Colonialism? Only if farmers were involuntarily made 'Carbon slaves' (as opposed to 'energy slaves') with a new paradigm of control. Ultimately, it should be a choice to buy/sell CORCs, CRCs, Carbon credits etc and even use software (desktop/mobile/cloud) to do it. There's also that question of converting these financial 'entities' into cash or cryptocurrency or both? Does Gaia care how it's done (possibly, as we are a part of her)? In one scenario, transparent 'blockchained' pit auditing with reflectometers and scales would be a bitch but would create many regional jobs in the process. National wireless/copper/fibre networks or global networks such as Starlink or even Oneweb etc could be used to upload/download information onto laptops/smartphones into hybrid software via the internet just about anywhere in the world but the internet service would need to be affordable and reliable.

Pioneering is speculation but before you drink the coolade perhaps initially or permanently, community level/involved/engaged projects with community crowdsourcing for RAS is the best combination, suggested by the lead software designer at regenfarmer.com The problem I can see there is crowdsourcing (spare) funds probably don't exist in large amounts in communities on most of the planet...unless it was internet-based crowdsourcing but most sites like 'Indiegogo' provide punters with something material...maybe some 'fair trade' coffee, for eg? Sounds fair but any exports have a Carbon footprint however platforms like 'Vaayu' are looking at tracking Carbon footprints for product supply chains at the retail 'point of sale'. Maybe this will help decarbonise the world economy? I imagine that at some point not-for-profit and corporate philanthropy has a role and some, but not all Governments, would cough up the cash for their farmers offsetting and reducing Carbon as well as growing cash crops, food and medicine. Who knows, maybe the next great cash crop will be 'Regen agroforestry' (as opposed to 'Carbon farming') and farmers won't even bother growing a monoculture of palm oil trees (cash crops) anymore or growing a monoculture of switchgrass (Carbon farming but love those phytoliths)? Ecosystems are biodiverse as should agroforestry polycultures be - the difference being 'economic' purpose. The plants grown in a RAS need to have multiple 'economic' purposes or functions that include providing ecological services, promoting biodiversity and Carbon sequestration for the planet - and besides, biochar has multiple functions too. Holarchies within holarchies. Interesting to note is the prominence that Bioenergy with Carbon Capture and Storage (BECCS) has taken in the latest 2021 IPCC climate report.

It's hard to imagine in Oz getting money from the Government for making biochar and putting it into pits while we are still developing coal and natural gas 'assets' (read 'climate liability'/cognitive dissonance)...

In Oz, it's sort of like on one hand, we've got most of the world telling the Government to stop burning fossil fuels and make a pledge for 'Carbon neutrality' in 2050. I believe this target, although scientifically fuzzy, at least galvanises international action. Maybe the planet will be Carbon-negative by then and addressing the volumes of CO2 already in the atmosphere and to come before 2050 'neutrality' (According to NASA, once CO2 is added to the atmosphere, it hangs around, for a long time: between 300 to 1,000 years). Don't forget the other greenhouses gases too! On the other hand the Government is in bed with the fossil mates riding the back of decades of climate misinformation leading to public confusion and investment so they can get away with it for a little while longer but not for long. According to the IEA, renewables are on the rise and non-renewables on the decline around the world. It's important to note that the world energy supply is just one source/sector of Carbon emissions - there are many others, so it's not contradictory to say that although renewables are increasing, Carbon emissions are steadily increasing too even with Covid-19. As I've previously blogged, the world's largest climate survey to date in January this year by the UNDP determined that 72% of Australians believe there is a 'climate emergency'. Borrowed time.

It seems we are going down two main paths - one of 'ecocide' and the other of 'ecosystem regeneration'. The 'ecocide system' is built into the state system architecture, according to Bill Boyer (1984) - this may be difficult to generalise now by today's standards given the efforts by some countries to decarbonise eg.UK. Digging Zai pits for 'ecosystem regeneration' isn't a waste of time or done in isolation as it's local and global action (glocalisation) and are even more critical to build due to their potential for 'geometrical replication' and are probably one of the 'safest' (safe climate) and most affordable and accessible options for biogeochemical Carbon sequestration. On a positive note, it seems everyday there are announcements of greentech breakthroughs that will get us to a Carbon-negative planet faster, hopefully by 2040 or earlier (fuzzy). Some of these breakthroughs are then monetised and deployed. The latest 'Western green energy hub' proposal for WA is the world's largest Green Hydrogen proposal to date :) It's another great example of 'geometrical replication' aka individual solar PV cells->PV panels and single wind turbines (a limited 'polyculture') multiplied to thousands. It's no wonder why so much R&D goes into producing the perfect solar cell due to the 'geometrical replication' effect - hence the need for 'Green chemistry' with a focus on C-based PV cells. By the time the project gets built (beyond 2028), the chemistry will be 'greener', efficiencies of these technologies will be presumably much higher than now and the green hydrogen production capacity will be even higher than currently stated - assuming the proposal is flexible for technology choice. Imagine if Hydrogen Systems Australia plasma arc electrolysers were used, which are 3 times more efficient than most electrolysers around the world...

From preliminary research, the pits are water saving, yield increasing, fertility increasing and more resilient to disease compared to some traditional methods of growing. The addition of biochar to the pits will further increase these gains as well as Carbon offsetting and reduction. I believe there are many possibilities and opportunities to replicate/scale up regen agroforestry systems but there's still a lot more research to do on this, especially regarding biochar systems integration. If you're interested in doing research in this area, please get in touch on the 'Contact' form and we can swap notes.

REFERENCES:

https://news.globallandscapesforum.org/50717/everything-you-need-to-know-about-drylands/

https://www.wineaustralia.com/growing-making/environment-and-climate/climate-atlas

https://en.wikipedia.org/wiki/Aridity_index

Try doing a google search for 'biochar Zai pit' - it seems this is a new field of research!!

Also, try doing a google search for 'semi-arid agroforestry'

https://www.researchgate.net/search/publication?q=semi-arid+agroforestry

https://www.ipcc.ch/report/ar6/wg1/ - try doing a search for 'BECCS'

https://regenfarmer.com/

https://puro.earth/

https://www.carbonassetsolutions.com/

https://nori.com/

https://www.vaayu.tech/

https://www.iea.org/reports/global-energy-review-2021

https://climate.nasa.gov/news/2915/the-atmosphere-getting-a-handle-on-carbon-dioxide/

Boyer, William H., 'America's future: Transition to the 21st Century' (1984), New Politics Publisher, Oregon, USA

https://newatlas.com/energy/western-green-energy-hub/

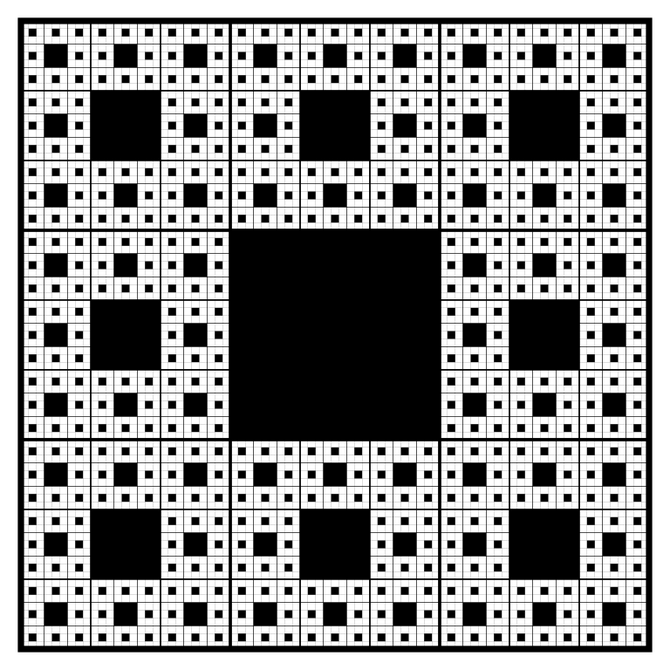

It would be possible to live in the centre of the fractal, if there is a centre? If there was a central water source eg.a bore or a well, or even large water tanks, it could make sense to build out around it if irrigation was needed but it would need to be protected from disease. Alternately, 'Measured Irrigation' produces large water bladders that could be decentralised throughout the pattern. Lu'au pits could be located in the 8 second largest black squares. Permafert pits could be located in the 64 third largest black squares. Zai pits could be located in the white squares. Keyholes/access points could be made connecting all of the Zai pits to the Permafert pits and Lu'au pits and 'centre'.

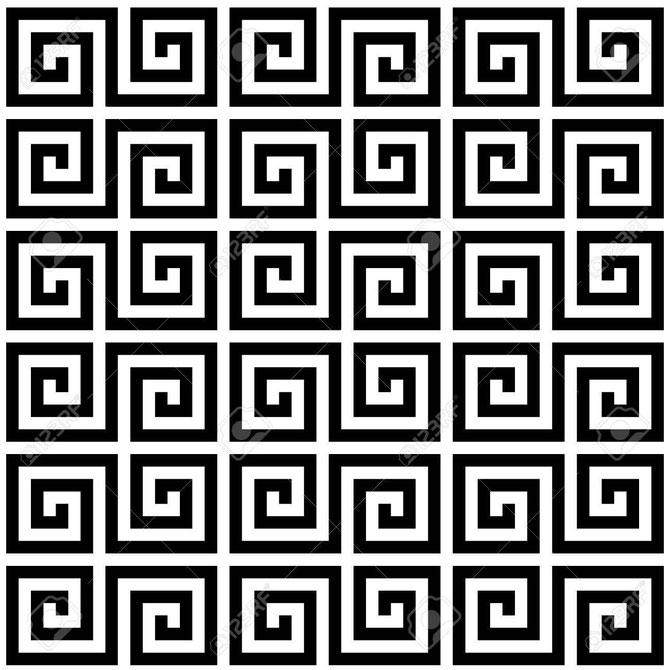

I came across a similar pattern to this 20 years ago when looking at some Incan textiles, in Cuzco, Peru. I like the Greek version as each spiral could be multi-layered canopy with taller trees on the outside gradating down to lower storey and more vulnerable plants in the centre, plus there's alleys for access that pass between the spirals.

There are repeating geometries/patterns found all through nature eg.spirals. Maybe it would be more Zen to live in a spiral design, square or circular, than fractal squares?

I think access to land, access to water, access to sustainable feedstock, efficiency of pit production, access to all the different pits and aesthetics should ultimately determine the topography of a RAS design...

-

How do you work out the amount of C per kg biochar?

RAS case study structure

Flooded! 5 of the 16 Zai pits (4,6,7,8,12) flooded after heavy rain - all were non-control pits (with biochar). After 4-6 hours, the water had drained. The next day, all the plants looked healthy in the flooded pits. This proves that the water harvesting design works as it is supposed to in some (42% of non-control pits) but not all pits and significantly, no control pits flooded which supports the idea that the biochar aquifers might provide a barrier to drainage which is good as it would increase the residence time of the water in the aquifers and possibly supersaturate them. I didn't measure their moisture content though - will do next time.

The difference across the pits could also be accounted for:

- variability in the effectiveness/structure of the berms to channel water into the pits

- variability in clay cracking at the base of the pits. Ideally, you would dig the pits and build them straight afterwards to avoid the cracking that possibly drains the pits more compared to the non-cracked pits - but maybe not

- Topsoil in the flooded pits may have been more 'sunburnt' than the other pits (slowing drainage/water infiltration) due to variations in sun shade across the pits. Importantly, I left the the pits for a few days in the sun before mulching them which may have made them vulnerable for the sunburn to occur. I think it's safer to mulch straight after the permafert is added to avoid sunburn.

I left all the pits and plants for 3 days before watering again. At this point, the top soil was very moist in the flooded and less moist in the non-flooded pits as expected. Next time I will use my moisture meter to get a more accurate reading of the moisture content in all the pits, calibrated to a non-control pit biochar aquifer with the '3 sisters'. The weather was warming up so I didn't take the risk of leaving the plants without watering for any longer.

Here's another possible configuration of the Zai pits. Rather than using the P3LS and flooding the pits, central biochar cores (medium milled), rather than a bottom aquifer have been added. If the Zai pits are slightly conical with the centre as the lowest point, rainfall will collect around the berms and concentrate on the central biochar cores for recharging the water. The cores could also be 'watered'. Water can wick from the cores into the adjacent permafert.

Similar to the square system but circular. Would take a bit more work per pit aka more time to build each pit. More water efficient in terms of water harvesting and concentrating the water into the central biochar cores. This system could work well on reasonably flat land.

I'm going to try this system next Winter but using a Kon-Tiki 'Rolls' for biochar production.

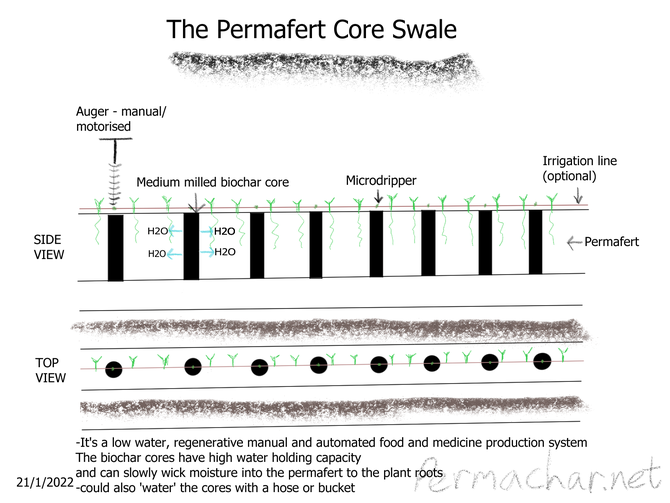

The above swale system could work well on reasonably flat land or even terraces and better than the Zai pits on hillslopes without terraces as they can be built slightly off contour for effective water harvesting.

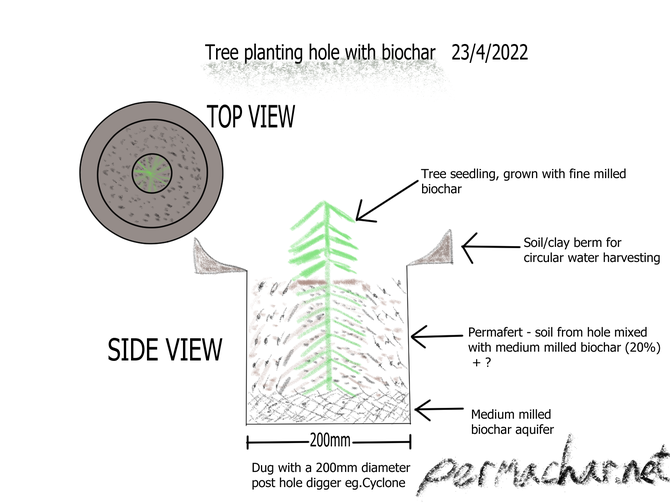

Tree planting hole with biochar

A variation on the circular Zai pit with bottom aquifer and no biochar core for tree seedling planting in a RAS.

What about the 'Flat-Tiki 'Carbon' V3'?

There is another approach to making the Permafert middens which uses less digging than a 'Lu'au pit' and is much cheaper than the Kon-Tiki 'Rolls' (KTR) - the Flat-Tiki 'Carbon' V3 (the design can be downloaded on the page 'Flat-Tiki 'Carbon"). However, the 'Carbon':

- Doesn't burn as cleanly or efficiently and is NOT 'EBC' approved like the KTR is!

- Has a flatpacked design for logistics which may be easier to transport to a RAS site than a KTR but once in the field, if you can get it there, a KTR is logistically better as it rolls on the ground

- Needs to be assembled and disassembled every time it is used which requires 2 people

- Is not as ergonomic as the KTR which easily tilts over after a burn for emptying the biochar

- Needs soil to put out a burn - water can deform the panels. Though, it can bake the biochar afterwards which may have an advantage to produce Terra Preta but ultimately biochar yield will go down if it bakes for days. When I was experimenting with it, I still needed a little water to completely stop the breakdown of the biochar after a burn but the kiln needs to be disassembled first

So, if you still want to build a 'Carbon', the kiln manufacturing requires a laser cutter, a bender for folding and 3mm steel, preferably HW350, If all the boxes can be ticked, this highly transportable kiln can once again be assembled at the location of the Zai pits. The biochar can be made, the fire is snuffed out at the top with ideally clayey loam, the panels can be pulled apart and what remains is the beginning of a small Permafert midden. For each successive burn, the kiln can be placed in a different nearby location and a new Permafert midden can be built. Additional ingredients can then be dug in to the midden and once the desirable blend is achieved, the Permafert can be shovelled straight into the Zai pits, with or without an aquifer. However, there's no reason why the bottom layer of biochar, after a burn, can't be separated and crushed to a medium grade for building aquifers in the P3LS.

Permachar

Permachar