See also the 'Biochar and water filtration' section on the 'Resources' page for articles and overview of desalination and general water filtration

Design notes

A scalable container water filtration system using gravity and Capacitive Deionization (CDI) for desalination if needed

Why not clean up the waste of the industrial and post-industrial age with affordable and simple appropriate open source biotechnology and provide Carbon sequestration (for reversing climate change), clean water (with desalination if needed), power production (for electronic devices) and enhanced food production?

WHS: As with fire, please be careful when experimenting with electricity. There may or may not be an open circuit in the CDI modules in this initial prototype however two research papers indicate that 1.2V is the nominal voltage across the biochar electrodes. All this needs to be carefully tested with safety a top priority.

Tools:

-electric drill with holesaw adapters - one for 2" pipe and one for the fermenter tap

-electric jigsaw

-silicone tube with dispenser

-standard straight hand saw for cutting pipe and beginning the cut for the jigsaw

-wire stripper multitool

-tin snips

-pH meter

-TDS meter

-multimeter with alligator clips

Materials:

Biochar

-unmilled biochar from the Kon-Tiki 'Rolls' - used in the water column/vertical pipe for initial water filtration

-milled biochar (from Kon-Tiki 'Rolls') for the biochar electrodes OR

-TLUD biochar for the biochar electrodes

*biomass from rice husk, sawdust, coffee pulp, bamboo fibre...all dried then pelletised with a pelletiser machine eg. FY-120 OR pine cones (crushed after pyrolysis) which have a resin that burns very hot

*all used for feedstock in the 'Permastove V3' (See 'TLUD (Top-Lit UpDraft) Stoves' page))

NOTE: A third cylinder in the 'Permastove V3' increases pyrolysis temperature in central reactor/cylinder and resultant increase of surface area of the biochar compared to a cooler central reactor in the majority of 2-cylinder TLUD stove designs. The increased surface area is good for filtration as it can absorb more water and adsorb pollutants or more importantly for the electrodes, it will also increase the electrical conductivity of the biochar, important for success of the CDI across the biochar electrodes within a CDI module/container

*replaces 'Activated Carbon' found in most water filtration systems eg. Aqua Blu

-four 20 litre opaque/white HDPE #2 containers

-1 metre long, 250mm wide section of PVC pipe (for the water column)

-Two 10 litre buckets - for adding the water to the water column and one for collecting the water at the end of the filtration system

-electronic components for Capacitive Deionization (CDI)(https://en.wikipedia.org/wiki/Capacitive_deionization) and see archives below

*1.7mm aperture 304 stainless steel woven mesh - for the biochar electrode modules

* Goal Zero 'Lighthouse 400'. You could run the 3 CDI modules with a USB dongle while charging yoursmartphone/tablet. Could be incorporated into 'The Energy Kit' (TEK) - see 'Overview of Permachar Systems' page)

*USB DC-DC step up/down voltage converter

*12V alligator clips x 6 - used to connect the step down converter to the electrodes

*electrical wire...1mm twin core - connected to the 12V alligator clips

*?modified USB cables/alligator clips for charging the powerbank (self-powering desal)

*150mm cable ties - used to build the biochar electrode container

-plastic fermenter tap with 'O ring' and swivel head for last CDI module water output

2-stage filter (the 'Permafilter'):

1-unmilled biochar from Kon-Tiki 'Rolls' (for vertical water column, half filled)

2-CDI modules for salt removal. TLUD biochar/milled biochar from Kon-Tiki 'Rolls' for biochar electrodes/capacitors

*powered by a powerbank that puts out power to 3 step-up/down converters and is ?powered by the desalination

https://www.offgridenergyindependence.com/articles/17852/energy-from-seawater

Add to the filtration system if the water is brackish, tested with a TDS meter (300-600 mg/Litre is the desirable salt concentration in potable water - any higher is unhealthy for human

consumption).

→potable water

-The spent biochar filtration media from both stages could be added to soil then phytoremediated using bamboo or other plants based on location/climate/accumulator parameters. Note that there is a balance of heavy metals that each plant variety likes. Filtered water could be used for irrigation (from a medium-scale system, 200 litre HDPE #2 barrels using the Aqueous Solutions design with a CDI stage at the last stage of the system if the water is brackish) if rainfall is insufficient to grow the plants

-The accumulator plants could then be pyrolysed in a Kon-Tiki 'Rolls' kiln (using filtered water for quenching and activation with additional product eg. liquid kelp)

-The biochar produced from the kiln could then be added to soil/Permafert to produce food plants with non-toxic levels of heavy metals (need to test plants for safe heavy metal level and confirmation of working filtration system) and irrigated, if necessary, from the medium-scale systems described above in series with a UMIC.

Learning Issues

1-Build the system then test it with various input water samples of varying quality/composition and measure the variables in the output water

2-Possible Stage 3 water filtration. Selective exoelectrogenic bacteria that can remediate heavy metals and produce electricity. A biochar MFC – exoelectrogenic bacteria that breaks down/remediates POPs, heavy metals, pathogens et al and powers the CDI with ?excess power for USB charging (via a USB interface) (could potentially use salinity gradients in the MFC too - see article under 'Microbial Fuel Cells (MFCs)' section) But - how to commercialise it or integrate it into cost-effective appropriate technology?

3-To what extent can biochar adsorb heavy metals using no bacteria and prevent them from leaching into the soil after the biochar has been used for water filtration and ended it's life cycle in the soil for plant production?

4-Are there better phytoremediation options (see bamboo article in zip file below) for removing heavy metals from biochar rather than capturing the heavy metals at the MFC stage of water filtration? Eg. the first stage of the two stage filter could be naked biochar, and after removing heavy metals could be transferred to soil to grow accumulator plants selective for the heavy metals removed (after a biochar sample analysis), then harvested for biomass to use in the Kon-Tiki biochar kiln. There is evidence that suggests heavy metals found in plants are stable in the biochar after pyrolysis (see sewage sludge article in zip file below)

5-Could functionalised 3D nanostructures be added to the biochar that could then permanently lock in heavy metals permanently during the water filtration process? This could be tested by growing food plants in the used filtration media/biochar and watering the plants with the filtered water. The plants could then be tested for presence of the original heavy metals found in the unfiltered water...if non-toxic heavy metal levels are found over time in subsequent food crops, the 3D nanostructures would be found effective at long term heavy metal sequestration. But - how to commercialise it or integrate it into cost-effective appropriate technology?

6-'Multifunctional biochar' (see zip file below) But - how to commercialise it or integrate it into cost-effective appropriate technology?

7-What is the best configuration for the biochar electrodes? eg.could they be fabricated then dropped into the containers like hard disks in a desktop computer? prototype DONE photo below. Each CDI module (3) will operate from the one powerbank

8-Can the potential difference across the first/second pair of electrodes be used to charge the CDI module powerbank due to ion transport in the desalination process? eg. could the CDI be self-powering...?

9-What is the desirable voltage across the biochar electrodes for a given TDS level, residence time of water in the CDI modules, feedstock and biochar-making tech? So, I need to make a chart with 'Voltage', 'TDS', 'Time', 'Feedstock' and 'Biochar-making tech'!

Capacitive Deionization

The half-buiilt 'Permafilter' biochar water filtration system - solid state apptech with no moving parts eg.pumps. It's like a 'Dragon kiln' in reverse - the water flows in the opposite direction via gravity compared to heat and smoke in the 'Dragon kiln'! The pipes with elbows will be siliconed at the container entry and exit points. The water column will also be siliconed in where it meets the container. The CDI containers can be removed by uncoupling the elbows from the pipe. The reason why the outputs are high rather than low is to maximise the residence time of the water for filtration. The whole system will be pressurised under gravity. The rate of water input into the water column needs to match the rate of output to maintain pressure so every so often the water column needs to be topped up when it reaches the level of the biochar. The input can be filled with buckets or a water hose. The electrodes will be tested with a multimeter with alligator clips. Just add swimming pool salt to water (25kg/bag)/use brackish water and check TDS and pH at the input and output of the system to see if it works!

The idea is that eventually 'Permafilter kits' could be sold with just the biochar electrode modules (without biochar), optional powerbank (which would be standard in 'The Energy Kit' (TEK)), USB DC-DC step up/down voltage converters, PVC pipe sections and elbows, fermenter tap, modified USB cables (if I can get self-powering desal working), silicone with dispenser and 2.5mm twin core electrical cable with alligator clips. In many places, the rest of the system could be sourced locally and adapted to suit local tools and materials.

I've found the white polyethylene 20 litre containers are easier to work on than the translucent containers which are more brittle. This unit could be used as a standalone CDI module or in series with more CDI modules.

I've tested the voltage with alligator clips on the stainless steel as well as probes inserted into the biochar and managed to get a stable 1.2V across the biochar electrodes using the Goal Zero 'Lighthouse 400' as a power source! Just need to test the desalination and tweak the voltage so I can make up a table for usage.

The 1.7mm aperture 304ss mesh will maximise the exposure of the biochar to the water for desal. The 1.7mm mesh holes are large enough that the zip ties can be pushed through OK for anchoring the electrode parts.

Operating instructions

General water filtration (TDS is in optimal range: 300-600 mg/L)

-assemble the system

-add water into vertical water column input

-collect water at output

General water filtration with desalination

-assemble the system

-connect powerbank USB outputs (3) to USB DC-DC voltage converters and set to 1.2V, 1 converter per CDI module

-connect converter outputs to wire +/- and attach alligator clips (on the other end of the wires) to +biochar electrode and - biochar electrode

*need to test..if voltage across electrodes is higher than 1.2V during desal, connect USB cable wire (remove USB A connector) with alligator clips to each module +/- and connect micro USB to converter (set to 5V). Connect converter output to microUSB input on powerbank - this will charge the powerbank during discharge creating a self-powering desal CDI module!

-install a plastic fermenter tap with swivel head at the last CDI module output OR use a plastic disc cut from a module during fabrication to cap a piece of 2" pipe (not ideal)

-the time of residence of the water in the modules will depend on the TDS (and feedstock and biochar-maker) which can be checked periodically until the TDS is in the optimal range

-when the TDS is at optimal range, collect water at output via tap or capped pipe...

-if the TDS is above optimal range despite desalinating for the recommended time period you need to flush the electrodes

*Flushing when TDS increases above optimal range

could reverse polarity of electrodes (attach the + wire/alligator clip to the - electrode and vice versa) and flush the system with filtered water OR remove the electrodes and empty biochar into a bucket with filtered water. Stir the biochar to wash it, drain it then add back to the electrodes and insert back into CDI modules for next cycles of desalination

Permafilter V2

Here's a much simpler design for water filtration - no sand, gravel or electricity. This version also has a tap for convenient water pouring. I added a 30mmx30mm fine 304 stainless steel woven sceening filter to the tap input then screwed it in which will filter out any fine biochar that wants to exit the container. The idea is to use 3 grades of biochar starting with 'Coarse'->'Medium'->'Fine' stages. I need to do some tests but it should in theory work for many different water chemistries. Ideally, I could use a biochar roller mill that had three different settings for coarse, medium and fine milling. The roller mill could also be used for the 'Permachar 3 Layered System' (P3LS) (medium for the aquifers and Biochar Mineral Complex (BMC) in the Permafert) and for potting mix (fine) too.

The 'Permafilter bucket'

The idea is that water vessels eg. Vacola glass jars, are filled with salty and/or contaminated water with a 1cm thick biochar layer at the top. The biochar black colour will absorb heat->increase surface water temperature for evaporation, the nano/micro/meso pores will filter salt and contaminants plus provide a wicking effect of water underneath to create a top level evaporation layer in the vessels. The evaporated water will condensate on the lid then move to the sides and trickle down to the bottom of the bucket. The biochar is dynamic and will shift with the water level. When the water in the vessels reach the bottom, they can be removed and the pure water can be retrieved from the bucket. I haven't tested it yet, but lets say every half a dozen batches the biochar will need to be removed and washed in a small amount of pure water to remove the salt and contaminants. Alternatively, after half a dozen batches, the biochar could be removed and replaced with fresh biochar.

There is a design from MIT that uses polyurethane insulation with holes drilled in it for thermal circulation but the problem I see here is that the insulation is fixed so potentially there will be an air gap between the bottom water layer and the insulation. Also, it is not clear how the water will be collected. Here's a link:

https://news.mit.edu/2022/solar-desalination-system-inexpensive-0214

Pasteurisation/Pasteurization

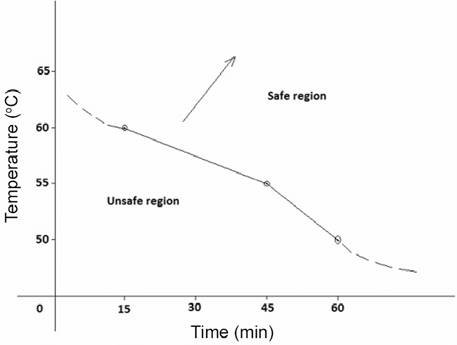

'Temperature–time relationship for safe water pasteurization. In the area above the line no colony forming units of coliforms' survive.'

Source: Nandini Nimbkar & Anil Rajvanshi, 'Simple filtration and low-temperature sterilization of drinking water', CURRENT SCIENCE, VOL. 104, NO. 4, 25 FEBRUARY 2013

OK. This could be used as a solar pasteuriser and will be tested in the coming days.

A 20L stainless steel bucket with a large clear saucepan lid on top. Three large Vacola jars, filled with approximately 1 litre of water per jar, were used with the steel lids placed on top for heat absorption and distribution (without a rubber band). I've added 1x10mm thick mild steel plate on top of each jar for additional heat absorption and distribution. If there were too many jars in there, the solar oven efficiency/heating would decrease. Two reflective stove heat shields taped together and to the centre of the bucket handle for additional light reflection to the lid. The reflector/lid/bucket creates a 'solar oven' for the vacola water vessels to heat the water.

If the water has unwanted chemicals, half a dozen small eg.1cmx1cm biochar pieces could be added to the water for filtration.

A stick was used behind the heat reflector at the centre of the bucket handle to adjust the angle vertically which is possible since the reflector moves freely with the bucket handle. Ideally, the reflector sits at an angle of 90 degrees between the sun and lid. The centre of the reflector also needs to align with the sun horizontally so the bucket can be rotated every half an hour to face the sun, using the base stubs of the bucket handle which don't get very hot. A steel vacola thermometer was placed in the bottom of the bucket and checked at each angle reorientation.

I tested the system today and success! At 30 degrees Celsius air temperature, between 1:30pm-2:30pm, the solar oven reached just above 50 degrees Celsius - high enough and long enough to 'safely' pasteurise the water. I checked the water temperature and it was 52 degrees Celsius at 2:30pm.

Also worth noting is the steel plate heat distributors were HOT - they seemed to be working very nicely.

Another option could be insulating the inside of the steel bucket with 10mm hemp insulation.

The whole system costs under AUD$100.

Permafilter 20L - A simpler gravity fed water filtration system

Built with 2 x 20 Litre food grade plastic buckets with lids (which may or may not be BPA free). Water is added to the top bucket and filtered via gravity through stones eg.scoria ->unmilled biochar->medium milled biochar->finely milled biochar->cheesecloth->dripped through a drilled hole pattern within a bottom central and circular footprint. This drilled area matches the diameter of a single hole sawed into the lid of the bottom bucket. In my system, it takes about 45 minutes for filtration. This time will vary from system to system.

Desalination

This is an experimental system. The initial testing is using freshwater but potentially could work with brackish or saltwater for potable freshwater collected in the bottom of the 100L (outer) stockpot.

Permachar

Permachar