REFERENCES

- Lenore, N. and Fraser, E.D.G., 'Dinner on Mars', 2022, ECW Press, Canada

- Diaz, C.J. et al, 'Developing algae as a sustainable food source', 2023

-

- https://www.frontiersin.org/articles/10.3389/fnut.2022.1029841/full

- https://www.permachar.net/tlud-top-lit-updraft-stoves/

- Google 'Pyrolysis of microalgae'

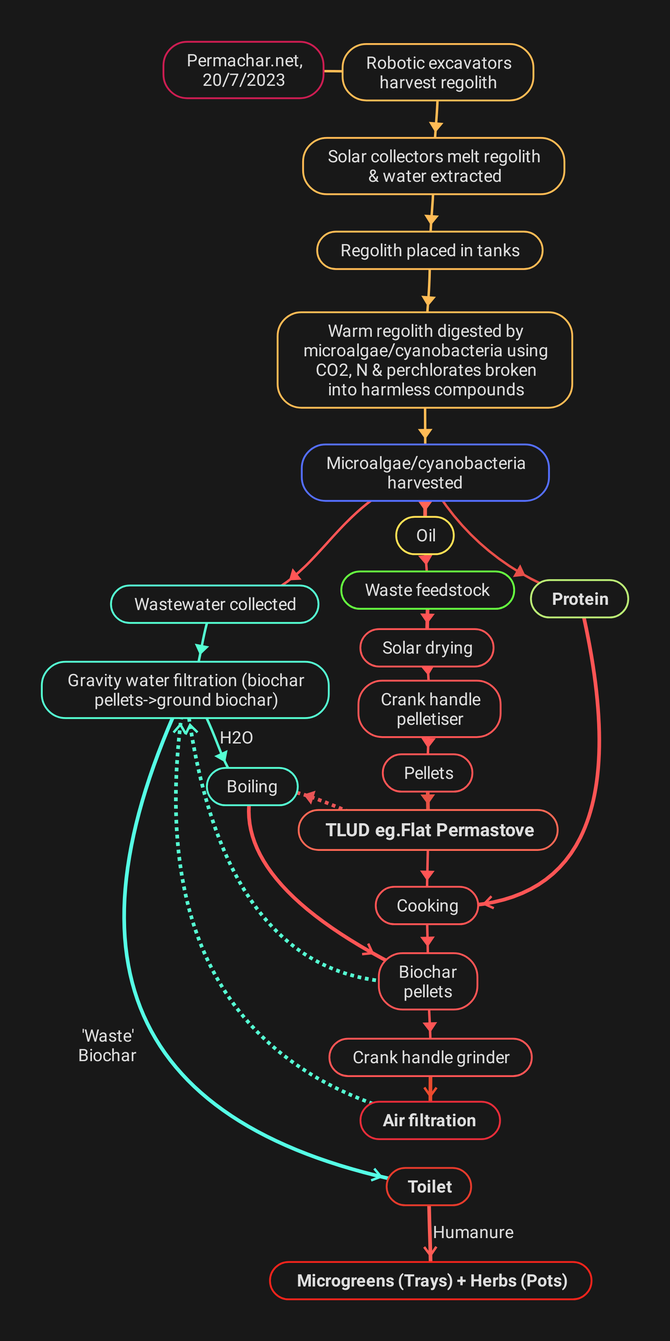

The 'Flat Permastove' TLUD stove that I am R&Ding could be a winner one day. Although it's using 2.5mm 304 ss at this stage, lighter and stronger alloys could be used in place since every gram of weight going to Mars costs money. The flatpacked design also reduces volume and once again cost. Below is a 3D model of the 'Flat Permastove'. It can be viewed with 'CAD Assistant'. There's also a section on my TLUD page for more information including the 2D design. Contact me if you want the dxf CAD file and we can haggle a reasonable price. Maybe together we can build something better?

The 'Flat Permastove' 3D CAD model - first prototype

Permachar

Permachar

Write a comment