Bush Survival System

This is a thought experiment with real/physical world application.

Linear degrowth transitioning to a circular regrowth bioeconomy? Sustainable adaptation? Carbon negative survival?

A backup or primary survival system using biochar for Carbon Removal in a Cascade of Uses (CRCU).

More for your biochar! Appropriate for 'on-grid' household (backup) or 'off-grid' household/bush shack/love shack/AirBnB/Tiny House/remote villages and communities/refugee camps etc. (primary).

This can change the game for sustainably meeting basic physical human needs.

Tech specs

- multi purpose

- pasteurization/WASH

- cooking

- can be used with biomass pellets eg. Wood pellets, in a Navigator Burner TLUD OR

- multi-fuel possible eg. Sticks, nut shells etc. in the space inside the bucket

- TLUD burner agnostic eg. Navigator '5 inch chimney flue' Burner (with a reduced chimney length) OK with 2.7 litre fuel reactor volume (1.8kg wood pellets)

- burner is heat and wind shielded by 20 litre ss bucket

- stovetop more stable and cheaper than the UPS

- ergonomic

- 34cm high stovetop

- easy filling

- easy quenching

- easy emptying

- water efficient

- quench water collected and reused for the next burn

- portable

- bucket handle can be used to transport it

- modular parts

- replaceable

- independent of each other

- scalable eg. 1+ units

- solid state

- no moving parts

- no electronics

- less cost

- no failures

- external power not needed

- completely DIY

- OTS parts

- 100% grinded

- no additional welding, folding, rolling or anything else

Parts/materials

- 20 litre SS bucket

- 30cm high section of 304 5" chimney flue tube

- 5 x 5 x 1.6 aperture woven mesh square (40cm x 40cm)

- 23cm bottom diameter SS wok ring

Construction

- if you're game to build a second prototype - the first prototype with 20L oil drum extender and higher 5" chimney flue chimney wasn't getting enough updraft with wood pellets. I've managed to

use less steel and bring the fire at the secondary air slots closer to the stovetop with the second prototype with better results so far than V1...note that there are no air gaps between the wood

pellets with the primary air only useful to convert the last biomass to biochar however if you want to use environmental fuel, with air gaps between the biomass particles, there's a possibility

that the first prototype with oil drum extender OR a humble 20L oil drum with the top cut off would work well with a 6" ss chimney flue with the same primary and secondary air slot dims as the 5"

chimney flue burner and 37cm overall height probably with excellent updraft (see the Navigator 'Awesome' Environmentalist at the end of the page).

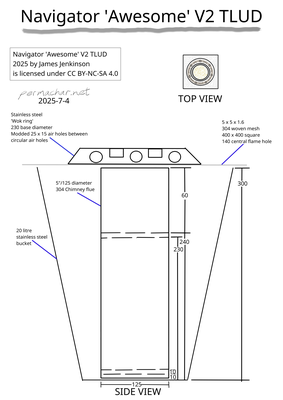

- drawings

- See diagram in photo gallery above

- tools

- standard electric angle grinder with 2.5mm thick disc (I use Makita discs) - probably a good idea to buy a few discs for starters. Need a power supply capable of powering

your grinder eg. grid (AC)/off-grid power bank (AC, but needs a minimum output wattage and correct voltage matched to your grinder power requirements). Or, a battery powered grinder (which I

don't have yet)!

- instructions

- 5" 304 chimney flue

- 300mm high (3 off 1 metre of flue(if building 3 burners)

- grind 2 rows of alternating slots for primary air at base (at 10mm and 20mm)

- grind 2 rows of alternating slots for secondary air (at 230mm and 240mm)

- mesh (see photo)

- grind 400mm x 400mm square

- grind a 140mm circle in the centre

- wok ring (see photo)

- at the top of the wok ring, grind 25mm wide x 15mm long squares, halfway between circular holes

Operation

- add tube to bucket positioned centrally

- fill the tube up to desired height below secondary air slots with biomass pellets

- squirt a ring of firelighter gel on top

- using a long stick/thin bamboo stake, add a little firelighter gel to the end and light then light the gel on top of the fuel

- add the mesh and wok ring

- wait for 3 minutes while burner starts up then start using eg. 15L SS stockpot for water pasteurization or pots/pans for cooking

End of the burn

- flame dies and burner will smoke

- quickly remove pots/pans and mesh with wok ring

- pour water into the burner tube at arms length with your head NOT above the burner due to HOT steam risk

- can use a 20L SS bucket with mesh top wired onto the handle (at the pivots)

- add water until above height of Biochar pellets

- remove burner tube with steel C clamp at the top and shake until all biochar pellets have fallen out

- stir in the biochar pellets into the quench water until zero smoke

- pour water and biochar mix onto the mesh covered 20L SS bucket

- Biochar pellets retrieved and quench water collected can be reused!

DONE

TESTING

1.2kg wood pellet testing

1st burn on Navigator 'Awesome' **V2**

- ambient temperature: 9degsC

- no wind

- 1.2kg wood pellets

- using 5 x 5 x 1.6 304 woven mesh with flame hole

- modded 230 base diameter wok ring

- 3m startup

- 14L water in 15L stainless stockpot

- t=0, 8degsC

- t=40, 53degsC

- t=50, 64degsC

- t=60, 72degsC

- t=70, 80degsC

- t=80, 86degsC

- t=90, 91degsC

- t=100, 94degsC

- t=103, 93degsC

- Burn time: 1h33m

- Biochar recovery: 98%

- pasteurization OK after 1h (reached 71 degrees Celsius)

1kg wood pellet testing

2nd burn on Navigator 'Awesome' **V2**

- ambient temperature: 12degsC

- slight breeze

- 1kg wood pellets

- using 5 x 5 x 1.6 304 woven mesh with flame hole

- modded 230 base diameter wok ring

- 3m startup

- 14L water in 15L stainless stockpot

- t=0, 13degsC

- t=40, 62degsC

- t=50, 71degsC

- t=60, 78degsC

- t=62, 78degsC

- Burn time: 1h2m

- Biochar recovery: 100%

- pasteurization OK after 50m (reached 71 degrees Celsius)

3rd burn on Navigator 'Awesome' **V2**

- ambient temperature: 9degsC

- slight cool breeze

- 1kg wood pellets

- using 5 x 5 x 1.6 304 woven mesh with flame hole

- modded 230 base diameter wok ring

- 3m startup

- 14L water in 15L stainless stockpot

- t=0, 10degsC

- t=40, 61degsC

- t=50, 72degsC

- t=60, 79degsC

- t=69, 83degsC

- Burn time:1h9m

- Biochar recovery: 100%

- pasteurization OK after 50m (reached 71 degrees Celsius)

4th burn on Navigator 'Awesome' **V2**

- ambient temperature: 14degsC

- slight cool breeze

- 1kg wood pellets

- using 5 x 5 x 1.6 304 woven mesh with flame hole

- modded 230 base diameter wok ring

- 3m startup

- 14L water in 15L stainless stockpot

- t=0, 13degsC

- t=40, 59degsC

- t=50, 71degsC

- t=60, 78degsC

- t=70, 83degsC

- t=77, 86degsC

- Burn time:1h17m

- Biochar recovery: 100%

- pasteurization OK after 50m (reached 71 degrees Celsius)

SUCCESS!

Average pasteurization time of 14 litres of water is 50 minutes using 1kg of wood pellets with the Navigator 'Awesome' V2 TLUD design.

Applications

- Appropriate for 'on-grid' household (backup) or 'off-grid' household/bush shack/love shack/AirBnB/Tiny House/remote villages and communities/refugee camps etc. (primary)

- Cooking

- WASH

- Biochar:

- -Boil/pasteurise the water (kills pathogens) then filter with Biochar (removes POPs, microplastics and other nasties)->Permafilter

20L->spent biochar->Bokashi and biochar dual toilet system (1- urine/liquid (add biochar), 2 - poo/solids (add bokashi and biochar))->Nitrogen doped/inoculated (urine) biochar (1) +

fermented humanure (2)->added to outdoor composting system eg.plus more bokashi and biochar, liquid sea kelp plus additional Carbon and Nitrogen biomass sources->growing systems eg.

Swales/Zai pits, wicking pots, fabric bags etc.->food and medicine

-A key barter.

-To scale up to larger quantities, I would suggest trying your luck with the flame cap 'Pyramid kiln' on the 'Resources' web page. This kiln can also be used as a fire pit, stovetop/BBQ and herb dryer too. If you want even more biochar, I would suggest the next step up is the flame cap Kon-Tiki 'Essential' (KTE) kiln (see 2 web pages).

-There's a Biochar Carbon Removal (BCR) credit option for the KTE with a couple of Carbon Removal Marketplace platforms and dMRV systems to choose from eg. Planboo app, the Biochar app (still at prototype stage) but you may need to establish yourself as a 'project' to get payment.

NOTES

- After a quench, the biochar and the quench water/'smoke water' can be separated eg. with mesh (eg. 5mm aperture) on top of a 20L ss bucket that will capture the biochar and let the water pass through. The quench water can be reused in the next quench and subsequent quenches (producing a 'smoke water' concentrate) and topped up with more water when needed or used (see below).

- If using the biochar for water filtration, I would recommend using the quench water only once to reduce tars on the biochar and ensure a pristine biochar for the water filtration

- In both of the above scenarios, the 'smoke water' can be used for watering seedlings, added to a biochar compost pile to keep it moist or for watering plants in growing systems, which has various 'soil food web' biological benefits

- Biochar inoculation can be performed in a water holding container eg. another 20L ss bucket. If you can access it, add some liquid sea kelp and microbiology eg. EM or Popul8 with some molasses (follow container instructions) to the biochar. The inoculated biochar can then be added directly to a compost pile or mixed with aged manure eg.poultry at a 1:1 ratio and added directly into growing systems either as a fertiliser eg.swales/Zai pits or as a complete growing media in wicking pots or recycled PET/PETE fabric bags (I've tested it successfully with basil, salad greens, tomatoes, curly parsley and 2 fig trees)

- I would recommend a soil quench only if water supply is super low, but the combined biochar and soil would not be suitable for the cascade and could be either left in the environment or in a domestic situation, used in growing systems, possibly with added ingredients such as liquid sea kelp, blood and bone, etc. but would not be as effective as direct biochar inoculation outlined above

Permafilter 20L

Built with 2 x 20 Litre food grade plastic buckets with lids (which may or may not be BPA free). Water is added to the top bucket and filtered via gravity through stones eg.scoria ->unmilled biochar->medium milled biochar->finely milled biochar->cheesecloth->dripped through a drilled hole pattern within a bottom central and circular footprint. This drilled area matches the diameter of a single hole sawed into the lid of the bottom bucket. In my system, it takes about 45 minutes for filtration. This time will vary from system to system.

Bokashi and Biochar toilet

Wicking growing systems

Conclusions

The BSS could be a 'turning point' for many parts of the world. While some Governments talk about 'climate emergency' and '(Just Green) Transition', or partially or completely ignore the climate crisis, appropriate technology in the hands of the people, in my opinion, will make the greatest difference to 'People and Planet'.

The high level of biochar integration in this system gets more 'bang for buck' out of the biomass using the biochar in a cascade but there is a long way to go for Carbon negative 'Biochar Civilisation' when 90% of global Carbon emissions are produced by the fossil fuel industry (according to the UN) and don't seem to be decreasing (fact check).

In Australia, there is much opposition to the 'Natural Gas'/'Unnatural methane' industry but is still getting approvals to expand anyway. The gas industry markets it's 'low Carbon' Methane as a 'transitional fuel'. Why not 'Carbon negative'? Is it really 'transitional' if new markets are being built to increase demand eg. Asia? In my opinion, methane gas is a 'vanishing fuel', not because we're about to hit 'peak gas' and a 'vanishing' gas supply (though in Oz, there seems to be an unlimited supply) but because as more households electrify and/or use biomass, gas demand will 'vanish' despite marketing and the chance of life on Earth 'vanishing' due to fossil combustion will decrease. On the household level Methane could be 'phased out' by TLUD hot water systems (eg. an 'Awesome HWS' with BCR credits to pay for the biomass pellets?) or electric heat pumps (powered by household renewables eg. solar, wind, micro-hydro etc.) replacing gas (or even inefficient electric) hot water systems, and TLUD stoves, replacing gas stovetops (with Benzene emissions), possibly by the Navigator 'Awesome' V2 (still under testing) and others too, such as the 'FabStove' (available in the US and South Africa but arguably expensive for the world market). If you already have an energy efficient electric stovetop powered by household renewables (which I do), why not use it as well as the TLUDs (which I also do), which could be primary or backup? On the grid scale, big batteries can be used for load balancing and dispatchable power (without needing gas peakers), preferably using sustainable battery chemistry such as saltwater eg.Redox Flow Desalination or Iron Redox Flow. I'm predicting in the next decade, even better Carbon-based battery chemistry (which could be Carbon negative) will be available for a range of applications with fast charge and fast/slow discharge and high energy density.

But - with all this energy complexity, the BSS can simplify your life, or be a survival line for limited access to resources, wallet, health and well-being.

Happy days!!

Navigator 'Environmentalist' V2

Here's an environmental fuel TLUD I designed using a 20L oil drum with radial slots grinded in the bottom, 2 rows of alternating secondary air slots on the sides (2/3 of the way up above the bottom) and primary air at the level of the mesh. Instead of using a 6" ss chimney flue, I decided to turn the whole oil drum into a TLUD using less steel, and one less part and supply chain. As per usual, the TLUD aims to produce biochar from biomass, which should be vertically stacked up to the height of the secondary air slots using less labor than horizontal stacking and creating a smaller, cooler and longer fire with higher biochar yield (though still pretty low for sticks). I used a Silky Gomboy 240 (10) bush saw to process the thicker wood eg.25mm.

This design is suitable for a soil quench with the soil and biochar returned to the Earth after a burn.

2nd burn

- ambient temperature: 9degsC

- no breeze

- vertically stacked mixed wood, 5mm up to 25mm, pine cones to fill gaps at the top, bark for tinder

- 5 x 5 x 1.6 304 mesh

- modded SS 230 base diameter wok ring

- 5m startup

- 14L

- t=0, 10degsC

- t=20, 77degsC

- t=30, 100degsC/rolling boil!

- t=40, still boiling, 100degsC

- t=50, still boiling

- t=60, still boiling

- t=65m, no longer boiling - just simmering

- Burn time: quenched at 65m

- Biochar recovery: 100%

- pasteurization OK after 20m (reached 71 degrees Celsius)

Permachar

Permachar