It's a strategy of designing, R&Ding and manufacturing renewable energy technologies with Industry 4.0 machinery, with a focus on Carbon removal in the form of biochar, initially for and eventually on Mars and future exoplanets and adapting the machinery, manufacturing and technologies to Earth conditions that are appropriate for a given location ('Spacialisation'). It's more of a design philosophy than a design system. Technologies for the future can be imagined then engineered for the present. It will take some major regearing for adaptation to the effects of climate change acceleration in the context of a climate emergency. It's a race to space but can lift more boats sustainably.

Carbon removal is urgently needed on Earth but would not be effective in stabilising the climate on Mars given the extremely high level (95%) of CO2 already in the atmosphere and predictable future small population with low biochar output but would be extremely useful, in the form of biochar, for air and water filtration, cooking and boiling water, sanitation, housing, 3D printer powder and food and medicine growing systems. In the materials world, biochar can do just about anything with a growing list of applications.

Here's the manufacturing algorithm...

Machines->Machines->More machines and other Machines->biochar Carbon removal tech + biomass->biochar->biomass->biochar...infinity. Biochar can also be used as a feedstock for some renewable energy technologies also produced by the Industry 4.0 machinery.

There are also bonus Carbon Removal Marketplace (CRM) options at the Origin of biochar produced, biochar in Supply chains and biochar at it's final sink/Destination...but - with Carbon Removal

for a Cascade of Uses (CRCU) the C sink is distributed through the supply chains, so Origin makes the most sense in my opinion for Measurement, Reporting and Verification (MRV).

Where to start? Imported/?Australian metal 3D metal printers (which may include some robotic metal 3D printers) and associated infrastructure to print metal components of their own chassis (essentially, self-replicating) + some specialty components (which we could potentially manufacture) to build more metal 3D metal printers to produce components for the Industry 4.0 machinery eg. production line robots for technology assembly eg.biochar mills and electric biomass pelletisers; multimaterial 3D printers for Solid State Batteries (SSBs) eg.Biochar/ceramic; roll to roll printers for mesoscopic Carbon perovskite PV cells (using biochar feedstock); 2D laser cutters for the Kon-Tiki 'Essential (KTE) biochar kiln, Permastove V5 and Flat Permastove V2 TLUD stoves, TLUD kilns for CharClay bricks; 3D laser tube cutters etc. The Industry 4.0 machinery could be sold to developing countries (or any countries) for producing their own renewable energy tech and whatever else they want to manufacture and puts them on the pathway to energy independence.

The manufacturing and resultant job creation (beginning with skilled workers teaching apprentices who would get a job at the end of their training) could be integrated with the ALPs housing plan. How? 'Industrial Ecologies', perhaps starting with one pilot project. Renewable energy tech machinery built in the industrial zone could build renewable energy tech for the ecovillages to house the local workers who could initially have temporary housing while the ecovillages are being built, which they could also help build while doing their tech apprenticeship. High thermal mass in the ecovillages would be critical for climate change resilience, as well as all the usual Permaculture refinements. I'm not against a biochar concrete supercapacitor for energy storage using Sublime Systems low Carbon cement either. Or - Why not prefabricated 'hempcharcrete' wall panels with Carbon neutral lime? Some Mars prototype housing could be trialled as well. The 'Mars Society' has a couple of test sites which are worth checking out. They are also founding the 'Mars Technology Institute' which will hopefully be up and running in the near future.

I do question the effectiveness of the Gov contributing 500 million bucks per year for five years for 1.2 million houses. I learnt division and multiplication on the 'Little Professor' calculator (now available as a free and ad-free Android app with 5 levels of difficulty) when I was 5 years old attending Church. Now I have a calculator app (RealCalc). So lets do the numbers: 5*500,000,000/1,200,000 = 2083.3 recurring. I estimate this would be enough to buy a couple of doors and a few windows. If, eg., the Gov staked 100,000 per house where occupants could buy in and cash out (the UK model) and it was done over 10 years, given supply chain problems with materials and a collapsing building industry and tradie skill shortage, the numbers would be: 100,000*1,200,000 = 120,000,000,000 or 12 billion/year over 10 years. Roughly a third of the cost of AUKUS. It's a question of the opportunity cost of Military programs V Social programs. Maybe a combination of Military and Civilian tech could be built in the Industrial Ecologies just to muddy the water. And there's the Unknown Unknowns.

If building the proposed pilot project for a 'Spacialised industrial ecology' is just a money problem, maybe we need our own equivalent of the U.S. 'Inflation Reduction Act' of 2022. The 'National Reconstruction Fund' is probably the closest we have but is basically a sectoral shopping list and isn't based on ecosystem thinking. We need to build momentum for manufacturing Industry 4.0 machinery and C removal technology, jobs and housing and do it sustainably. At some point the private sector needs a financial boost to generate more investment for more industry and more tax revenue to pay off interest on debt - who knows, the Gov could even get ahead by investing in a fossil free sustainable future? We need to keep brains in Australia, beef up STEM skills and education, train highly skilled apprentices ready for Industry 4.0 and avoid the renewable energy brain drain to the U.S. eg.Engineers.

What's the alternative to manufacturing machinery, tools and consumables? Fuel exports. Selling Industry 4.0 renewable tech machinery is a more supply chain resilient, lower C footprint,

accessible and ethical approach than exporting fuel, whether it be fossil, 'low C' Methanol (from CCS (if it works), Direct Ocean Capture (DOC) of CO2 to methanol; CH4 to methanol using an

enzyme catalyst) or even 'C neutral' fuels such as 'Green Hydrogen'; which are all akin to selling an addictive substance and creates a dependency for other Nations' growth and development - the

old Imperial business model. Industry 4.0 machinery for producing renewable energy tech would be a once off investment for punters, modular enough that printing new parts for failed parts in

existing machinery is possible or new purchases could be made for better machinery without major capital expense for new infrastructure eg.grid power/expanding off-grid power and could be built

to last (durability) with upgradeable free 'open source' software and firmware. It's a safer bet than betting the house on any specific fuel that will probably become outmoded in the future.

The boat just rocked in the transport industry. Solid State Batteries (SSB) for passenger EVs just exceeded 1000 mile range from 3 different companies. The UK has canned it's first Hydrogen train line citing inconvenience and cost. Twiggy's Hydrogen dump trucks are 3 times less efficient than EVs (probably not even using SSBs) though they are still trialling them. Japan's Hydrogen plan is not working. Methanol not Green Ammonia, is taking over shipping. The aviation industry is R&Ding both Hydrogen and electric models - but I bet electric will win with the next generation of energy dense and safe SSBs. An e-bike from Switzerland using a ceramic electrolyte in an SSB has just been announced. Pulsed plasma rockets will go damn fast. If you get the idea, many things are being prototyped in the transport industry so I think it's highly risky to build yet another fuel industry. Ideally transport could harvest, store and use energy independently within the system design of the vehicle.

There's also the issue of 'Economic Complexity', which we are ranked 93 in the world.

https://atlas.cid.harvard.edu/rankings

A robust manufacturing industry, with a focus on renewable energy technology for Earth and Space using Industry 4.0 tech and principles would lift our ranking and diversify the economy for greater stability. What's also bizarre is that we have one of the greatest culturally diverse people on the Planet...so why are we ranking so low? Biodiversity, biomimicry and cultural diversity can fight climate change and help adapt to an increasingly uncertain future. It may be a future of buggy firmware for system design but I/We can keep learning and improving our positions and livelihoods.

REFERENCES

https://www.abc.net.au/news/2023-08-03/australia-space-industry-cuts-730/102683954

-we might need some of that cancelled space program money for the pilot project

https://www.pv-magazine.com/2023/09/15/printable-mesoscopic-carbon-perovskite-solar-cell-achieves-17-13-efficiency/

-getting there nicely for PV printing and C usage

https://phys.org/news/2023-09-carbon-footprint-methane-methanol-enzyme.amp

-possibly the last gasp for the 'unnatural gas' industry. Land and sea based gas mining are both unsustainable.

https://newatlas.com/architecture/mit-concrete-supercapacitor/

-think buildings can store their own energy possibly sourced from solar glass and rooftop PVs in the concrete structure (using biochar/other C material). Probably needs a greener acid chemistry...

https://carbicrete.com/technology/

-not a bad option for C negative concrete BUT could be a thermal mass problem for climate heating

https://sublime-systems.com/

-low Carbon cement

- Hempcharcrete

https://medium.com/x4lime

-Carbon neutral lime

https://www.homelandhempcrete.com/

-prefab hempcrete walls

https://www.etsy.com/listing/850267664/diy-biocharhempcrete-diy-kit-with-recipe

-also from homeland hempcrete

https://www.abc.net.au/news/2023-06-01/industrial-hemp-vying-for-victoria-government-boost/102415910

-a bit of hemp action in Victoria, Australia

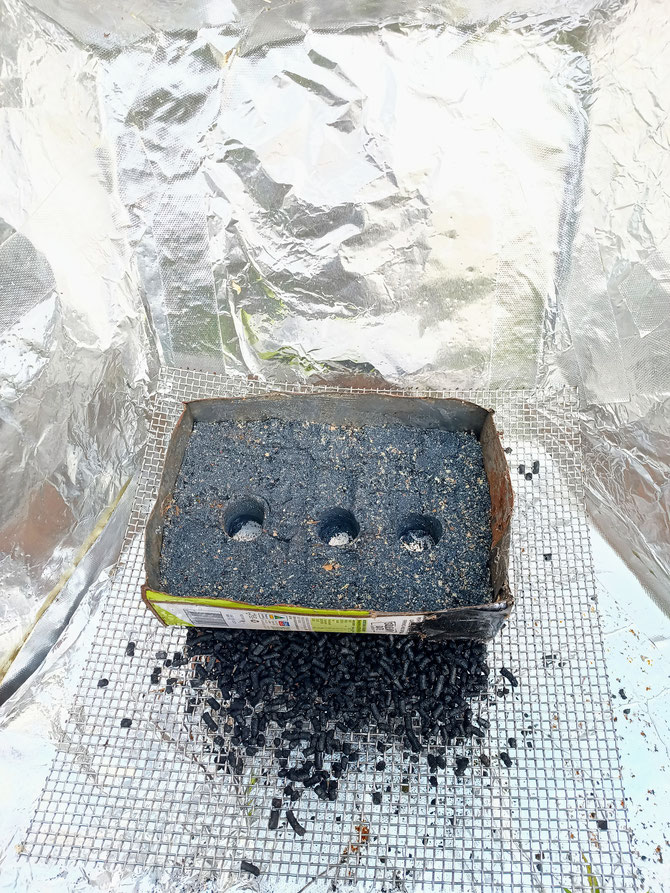

Potentially, the CharClay brick could be larger eg.size of a besser block, and fired in a medium scale kiln running on biomass that produces biochar as a by-product. This biochar could then be milled to a fine grade to produce/add to more bricks. Ideally, the clay could be mined at the site of the kiln. I just happened to have bentonite granules on hand but I do have brown, red and yellow clay I can experiment with on site. The kiln could use TLUD first principles for clean emission production of heat and biochar. A 'Carbon negative' outdoor shithouse/toilet for producing humanure-biochar compost will be my first project. The compost can then be used in growing systems eg. Tree Guilds.

Alternatively, the TLUD kiln could fire terracotta, produce biochar as the by-product, both are milled on site to a fine powder and combined at the ideal ratio (possibly not yet R&Ded) to produce a powder for 3D printed Solid State Battery electrolytes, probably at a second site with better logistics access. The ideal kiln site would have a combination of the right clay on site and ?waste feedstock that can be processed for the TLUD fuel also on site. The kiln could have modular impermanent assembly and moved to different sites if needed. In-Situ Resource Utilization (ISRU) and Permaculture are interesting areas to guide this system design thinking.

I suppose you could use a solar-powered electric kiln but you wouldn't get your bonus biochar through cogeneration. If anyone is interested in financing R&D, I've got a couple of leads for the kiln design.

Alternatively, this company is researching 'no-bake binders' with biochar to produce biochar bricks.

https://composite-designers.com/net-zero-construction-materials/

https://www.stockholmresilience.org/research/research-news/2023-09-13-all-planetary-boundaries-mapped-out-for-the-first-time-six-of-nine-crossed.html

This research should inspire motivation for more Earth care as opposed to being paralysed by fear of uncertainty and imminent doom resulting in inaction and delay. It doesn't seem to bother New York protesters.

https://www.aljazeera.com/news/2023/9/18/tens-of-thousands-rally-in-new-york-demanding-end-to-fossil-fuels

Technology can make many people's lives easier and can reduce our Earth footprint, survival is necessary and can be appropriate but it's not the whole game.

Permachar

Permachar

Write a comment