Wed

22

Oct

2025

Atmospheric Water Harvesting panel and dew irrigation system

Here's a business proposal. If anyone is interested, please get in touch on the 'Contact' page...

Here's the idea:

Nanochloropsis/other microalgae genus with an appropriate endemic strain (grown in brine 'wastewater' from 'Redox Flow Desalination' of seawater, in long raceway ponds)->dried->pelletised->Charcell 3 or 4 (or other suitable biochar kiln)->pyrolysis->Biochar pellets (CDR credits)->(process heat from Pyrolysis->steam activator)->steam activated Biochar pellets->milled->biochar powder + organic linkers + Manganese (Mn) (eg. 'One pot' or 'ball milling')->biochar-Mn Metal Organic Framework (MOF) (tunable hydrophilicity switching) -> Atmospheric Water Harvesting (AWH) panels->spent media at end of lifecycle (?years, relative to climate zone eg. semi-arid, arid, and climate change)->soil, for growing system (variable amount of 'toxicity' to soil food web, could work as a "dew irrigation" system)/permanent Carbon sink

Here's some eye watering AI intel from perplexity.ai 'Research' using web and academic sources.

Searches:

steam activated biochar Mn MOF for AWH panels

is Mn-MOF non-toxic to soil

does biochar Mn MOF show hydrophilicity switching

Conclusion

"Biochar Mn-MOF composites do exhibit hydrophilicity switching, arising from the interplay of MOF framework flexibility (breathing), stepped water adsorption behavior, and biochar surface wettability transitions. This switching is advantageous for AWH applications, enabling efficient water capture at low humidity and facile release upon heating. The switching threshold can be tuned through synthesis parameters including activation temperature, MOF linker selection, composite ratio, and defect engineering. Understanding and optimizing this switching behavior is key to maximizing the daily water production capacity of MOF-biochar AWH panels operating across variable ambient conditions."

Here's the next prompt: "steam activated microalgae biochar Mn MOF for AWH

Conclusion

"Steam-activated microalgae biochar integrated with Mn-MOFs represents an advanced AWH material leveraging the unique compositional advantages of algae biomass—particularly high nitrogen and oxygen content, beneficial mineral ash, and protein-derived functional groups. The nitrogen self-doping capability creates multi-site water adsorption chemistry complementing Mn-MOF coordination sites, while steam activation develops hierarchical porosity enabling efficient water transport. The resulting composite exhibits stepped water isotherms ideal for AWH across variable humidity conditions, with enhanced photothermal properties facilitating solar-driven desorption. Integration of algae cultivation with wastewater treatment and the carbon-negative lifecycle position this material system as both high-performance and environmentally sustainable for addressing global water scarcity through atmospheric water harvesting panels."

What do you think?

Tue

07

Oct

2025

3 ways to cool the Earth

The problem

- a simple strategy for C emissions is needed

- Short term/impermanent C removal eg. Forest monocultures via offsetting (with potentially no C emissions reduction of operations) V permanent C removal and real C emissions reduction of

operations (for a Net Zero or Net Negative operation)

- C emission reduction targets are compared to a C intensive baseline year (2005) though I'm not suggesting abandoning them. More action is needed!

A simple strategy algorithm

1. 'Avoid' Carbon emissions

1. 'Phase out' fossil fuel and replace with renewable energy

2. A 'Fossil Carbon export tax' (and possibly a selective 'Fossil Carbon import tax') could be a good start

2. 'Reduce' C emissions

1. 'Decarbonisation' eg.Climate Safeguard Mechanism (CSM), though practical in many cases, won't work alone

3. 'Remove' Carbon emissions

1. 250 years of Industrial Carbon emissions, to a degree, still exist in the atmosphere

2. Arguably the 'Real Transition' where most of the work needs to be done

3. 'Recarbonization' and 'Regeneration' with Biochar will work - Carbon can be our friend

4. Using 'C negative tech' with biomass waste to Biochar

Recommended objectives for Oz:

- A 'National Pyrolysis Strategy' is needed to build a 'Permanent Carbon removal' economic sector, with a possible National Carbon Removal Marketplace (CRM) to replace ACCUs. Denmark got the ball

rolling. It's a new technology and Gov mindset that should be easily politically achievable with the right leadership.

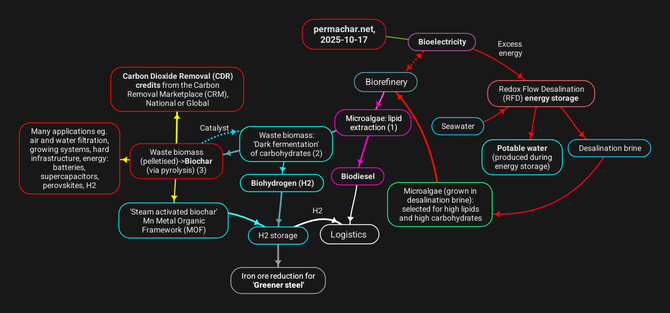

- eg. Somewhere in the South Australian coastal desert, biomass pellets (made from seawater grown microalgae biomass process waste, after lipid extraction for health supplement

and/or biodiesel)->bioelectricity and biochar->Redox Flow Desalination->potable water and energy storage->powering 'Green Hydrogen' electrolysis (potable water or ideally

seawater)->H2 for iron ore reduction->'Greener steel' (essential for just about every 'C negative' tech I've researched, designed, built, tested and developed. The pre-commerical aspect

needs pre-seed funding and the commercial aspect needs seed funding available or VC, which is a pain in the arse which the minority of punters ever secure)

- the above idea demonstrates that 'Avoid', 'Reduce' and 'Remove' can all occur in an industrial process chain. 'Avoid' is producing biodiesel for logistics rather than importing

hydrocarbon based diesel. 'Reduce' is using 'Green Hydrogen' to decarbonise steel production. 'Remove' is producing biochar for permanent C removal while producing bioelectricity.

- By 2035, 80% of Oz businesses are at least C neutral using a combination of 'Avoid', 'Reduce' and 'Remove', eg.

- replace/'Avoid' C emitting energy sources with C negative (removing) energy sources and Biochar battery/supercap storage

- substitute/'Reduce' C emitting products/materials with Biochar based products/materials in supply chains and materials (biosubstitution), for greater circular bioeconomy

('Carbon Removal in a Cascade of Uses' (CRCU))

- purchase CDR/BCR credits from ideally a National CRM platform ('Remove') and keep the wealth and 'Regenerative transformation' in the Country, OR

- purchase CDR/BCR credits from a global CRM platform ('Remove'), such as puro.earth, carbonfuture.earth, milkywire.com et al

- Digital Infrastructure subsidies for SMEs (Large enterprise can pay for it's own)

- eg. a data pipeline

- CRM platform<->Carbon accounting software->ESG reporting + GHG inventory->C emission reduction targets

For those that want to be at the Charface of the Carbon Removal (Industry) Revolution, I suggest signing up to the free newsletter called 'GigaTen' hosted by Sebastian Manhart here:

https://www.sebastianmanhart.com/gigaten

That's all for now...

Mon

22

Sep

2025

Manufacturing mayhem

How we adapt to climate change is the future we build together and hopefully want.

We need to align our survival needs with other species survival needs.

What's the point of adapting if the adaptation produces more problems?

Even sustainable adaptation could create more problems...but, presumably a lot less than unsustainable adaptation.

'Green steel', essential for biochar kilns and stoves, and many other applications, is a sustainable adaptation in the sense that 'Green hydrogen', used for iron ore reduction, can be produced

from renewable energy and seawater. The logistics of mining and transportation of iron ore can also be electrified. But it doesn't solve the problem of additional minerals added, many imported,

for ?many of the final steel products. The solution could be to use 100% Australian minerals but this might not be possible due to those minerals not available in Australia or are not in

'economic' geological deposits. Maybe new steel alloys could be designed that can utilise Oz minerals and is 'economic'? The reality for most of Oz industry is that many sustainable adaptations

can be made but may not be able to be 100% sustainable, or even 'Carbon neutral'/'Net zero'. Should this mean abandon the industry or is it that better industry design is needed eg. reimagined

and rebuilt for the 'Circular economy/bioeconomy' or something else?

So, I want to make a few points about manufacturing:

- A 'Carbon negative' technology future could be mined, grown, made and affordable in Australia (and elsewhere too).

- Regarding plants grown, fast permanent C removal needs fast plant C sequestration with waste biomass converted to Biochar with 'C negative' tech.

- A flagship technology could be built, such as a 3D printed solid state steam activated bamboo biochar ceramic Mn MOF battery that could benefit the people and Planet, but needs a lot of design work and R&D first, with a skillset I lack and no financial resources. I'm happy to discuss it with anyone interested. This design combines Earth abundant and sustainably managed bamboo with Earth abundant Mn and possibly Kaolin clay using the best manufacturing technology available.

- Artisanal/small-scale manufacturing or large scale manufacturing? Ultimately flexible factory floors with Industry 4.0 and robots could be a winner for scaleable production on the large scale.

- Sustainable and Sovereign manufacturing base?

- A focus on manufacturing tech for Civilian, Military or both?

- Complexity is everywhere in manufacturing. A reduction of the complex to the simple is needed.

- Some apptech could be considered as greentech but not all greentech is apptech!

- Neither greentech nor apptech is necessarily Carbon negative tech

- Carbon negative tech could be either greentech or apptech or both

- Open source or closed box manufacturing? The key to 'open source' greentech/apptech/C negative tech, is baking in an invisible mainframe (eg.flame cap, TLUD), which will vary from one tech to the next, based on science. Then the tech, based on the mainframe, can be built just about anywhere where appropriate tools and materials are available.

Where is it going?

Globalisation is now King, both from above and below.

However, it's probably the end of reliable and predictable Globalisation from above.

Global supply chains are the new norm for most manufacturing which could be a problem for many Countries if known unknowns (or even unknown unknowns) tip the apple cart.

Trump and his tariffs are shifting shape on a regular basis and could tip, or already has tipped, the apple cart (a known unknown).

Free trade is a list of trade exemptions.

Trade is diplomacy and war!

But, trade is now mostly done with any Country and any Corporation on the Planet.

Consumers win until they lose - the Gov needs to help them win.

I believe there are unlimited jobs for climate change adaptation since the problem is getting worse, linear energy systems need to be replaced with circular ones, a lot of infrastructure needs to

be upgraded and many technologies, possibly 'Carbon negative' tech, could be manufactured.

Tue

16

Sep

2025

Carbon chemistry

Try these in perplexity 'Labs' if you're interested in the cutting edge of 'Carbon negative' biochar energy applications:

"ceramic biochar Mn MOF for solid state battery electrolytes"

"steam activated bamboo biochar for Mn MOF Hydrogen storage at ambient temperatures"

then "bonding characteristics". I was particularly impressed with the increased H2 bonding sites on the biochar which also stabilises the H2 bonding to Mn oxides though this intel is definitely debatable.

The competition is h2mof.com

"top 10 academic research papers on steam activated bamboo biochar anodes"

an 'aha' moment, using perplexity to rank academic research papers based on a variety of factors

"steam activated bamboo biochar anode comparison to other anode materials".

Could this be the end of the graphite anode industry?

Also, KOH activation was beaten on cost and sustainability compared to steam activation (but not surface area, which is still excellent with steam activation). Once again - debatable.

The main impetus for these searches is to use Earth abundant (mainly in the tropics) and fastest CO2 accumulating plants, bamboo, for Carbon removal in tech, with an Earth abundant mineral, Manganese (Mn) with high redox potential (and no rare Earth monopoly) for energy storage. The use of ceramics with activated biochar based MOFs is on the cutting edge in my opinion. Not sure what the Carbon footprint and water footprint of mining clay is, but it's probably a lot cleaner than mining many other minerals.

Have fun, and I would suggest using the research as a starting point for further academic research (aka reading real academic research papers).

Still grappling with the context problem for the paper references.

There are other AI research software platforms that address this issue but are not as advanced as the biggest Chatbot on the Planet.

Any feedback please get in touch on the 'Contact' page.

Tue

26

Aug

2025

What factors contributed to biochar's success?

What factors contributed to biochar's success?

A 'Climate Emergency Renaissance for a Circular Bioeconomy'

- 'Cradle to Cradle' (circular) or 'Cradle to Grave' (linear) Carbon Removal in a Cascade of Uses (CRCU) with end of cascade Carbon sinks in either soil to grow more plants with all it's associated benefits (circular) or hard infrastructure (linear)

- Plant industry revolution, with fast CO2 accumulator plants selected for food, medicine and material feedstocks, including increasing amount of biomass waste converted to biochar with pyrolysis

technology

- Investors cash/Corporation's cash aiming to achieve a Net Zero operation by purchasing Carbon Dioxide Removal (CDR)/Biochar Carbon Removal (BCR) credits from the Carbon Removal Marketplace

(CRM)

- Permanent Carbon removal

- Maturation of the CRM and related platform infrastructure

- smartphones eg. dMRV apps integrated with CRM platforms for BCR credits earned by Charistas for producing biochar

- need for post-quantum/'quantum proofed' platform (anyone interested?)

- Pyrolysis technology revolution

- small to medium sized biochar stoves and kilns

- Top-Lit UpDraft stoves (TLUD)

- Champion 2008

- Fabstove

- Navigator 'Backup' V2

- Navigator 'Awesome' V2

- TLUD oil drum kilns eg. Warm Heart Foundation

- larger TLUD kilns (experimental)

- flame cap biochar kilns

- pyramid kilns

- Kon-Tiki kilns

- panel kilns eg. Flame Cap 'Algorithm' Panel Kiln, 'Obtainium' (use what you can get) panel kilns etc.

- large biochar kilns

- combined biochar, heat, bio-oil, wood vinegar and bioelectricity options

- eg. ECHO2, CharCell, CharMaker, Joey's open source trough pyrolyser etc.

- related biomass and biochar hardware

- pelletisers

- mills

- chippers

- chainsaws

- bush saws

- Charistas and communities rising to the challenge, often motivated by a desire to exit poverty and produce higher crop yields while saving water, fertiliser and chemicals

- Expansion of logistics networks, electrification of transport (in progress) and efficient and powerful logistics software systems

- Rate of global Carbon removal with predictions of Gigatonne scale removals by 2030

- Biochar applications

- water filtration eg. small scale (Permafilter 20L) to large scale (mine sites, stormwater etc.)

- agriculture/forestry/agroforestry/horticulture/permaculture eg.regenerative farming, regenerative agroforestry etc.

- plastic pyrolysis upcycling->plastic char->Flash Joule Heating->graphene, bio-oil->Ultra Low Sulfur Diesel, monomers to new plastic etc.

- advanced new materials eg. bioplastic filler, graphene, electronics, batteries (bamboo), perovskite C backed PV cells, supercapacitors (bamboo), Carbon fibre filler etc.

- hard infrastructure eg. charcrete, hempchracrete, paving, roofing tiles, bitumen filler etc.

- many more

And, most importantly:

- The good will of the people who want a living Earth for future generations

Sat

09

Aug

2025

Climate emergency Renaissance

I'm a technologist with an interest in not just technology but also the politics of technology - or, 'technology politics'. I blogged a while ago that sometimes technology and politics get mixed

up. They have got mixed up. There's now an energy war, with the technology of energy, and the competition of ‘linear energy systems’ V ‘circular energy systems’ ramping up. A real ‘transition’ is

when linear energy systems get replaced with circular energy systems – circular energy systems being the kernel, if you like, of ‘Circular bioeconomy’. Yes, there's a grey area in between the two

systems, especially with fossil fuelled logistics (which can always purchase Carbon Dioxide Removal (CDR) credits from a Carbon Removal Marketplace (CRM) platform), but I would argue there's not

much in between and not much time left for the breaking climate system and the choices we make to sustainably adapt to it in order to make the switch. I call it a ‘Climate emergency

Renaissance’.

How to fund it? I believe the best source of income in Australia is, rather than taxing working people for the transition (including fossil workers), up the ante and introduce a 'Fossil Carbon

export tax', pioneered by Prof Ross Garnaut and Prof Rod Sims. Additionally, the 'Fossil C import tax' would be good for many/all? fossil eg.Natural Gas (NG) or fossil derived products eg.coal

briquettes, except for petrol and diesel. There's also only 2 operating oil refineries in Australia with limited oil mining in the Country. Obviously, we need to get off petrol and diesel and

will increasingly do so with electrification of civilian and possibly military logistics but an import tax that hits commuters in the hip pocket in the mean time is not a great idea, especially

with the 'Cost of living' inflation problem. It seems pointless to tax petrol and diesel imports then subsidise them. There's also a possibility of condensing bio-oil from plastic pyrolysis

(addressing the plastic waste problem) and converting it to Ultra Low Sulfur Diesel (ULSD) which burns cleaner than regular diesel with the bonus of a plastic char byproduct that can be used as a

feedstock to produce advanced Carbon materials. There's also a possibility using microalgae for biodiesel, though seawater grown microalgae in near coastal areas would be the most sustainable

option. Finally, in my opinion, the Country should reluctantly milk what fossil fuel we are currently mining and ban future fossil mines and expansions.

Undoubtedly, there’s a contractual problem with fossil fuel exports with various types of contracts already in motion in this space. We could treat it like China treats it’s rare earth mineral

monopoly and game it so the contracts remains globally competitive but tax as much as possible. Not that it would bother me if it did become noncompetitive which it probably will be anyway over

time, but it seems like a great source of Gov revenue that is more or less untaxed! I agree with the late Hugo Chavez’s idea to use fossil wealth to 'float more boats' (which requires taxation)

but I disagreed with his idea to put an oil pipeline through the Amazon rainforest which is already under logging, oil mining and farming pressure. If the infrastructure is environmentally or

culturally damaging, then it shouldn’t get built. Ideally, wealth could be achieved without any fossil fuels. Also, there’s the issue of the 'Natural Gas' shortage on the East Coast, and possibly

elsewhere? It’s an artificial shortage, that, like Santos, has committed to fossil exports without first supplying NG to meet domestic NG demand. Mark Ogge, from the 'Australia Institute', wants

a National Reserve of NG. So do I.

But, I’m also working towards meeting that NG shortage with a semi-retired 'Top-Lit UpDraft' (TLUD) business that could provide stoves to replace NG stovetops using biomass/wood pellets but due

to indoor fire restrictions and safety, the system would need to be used outside, but could be viable in most other countries with no indoor fire restrictions. I also wanted a cheaper system than

the Fabstove, that is half the price and provides 2 burners without needing any electronics to cover most water pasteurization (though not needed if you’re connected to the water grid) and

cooking options.

So, from what I've read so far, I would describe the Renaissance period as a great case study for understanding the climate emergency. I tried searching perplexity.ai with this: "could the

climate emergency be a tipping point for a circular bioeconomy Renaissance?" There are some gobsmacking parallels between 'Renaissance' and 'climate emergency' which can inform how this new

Renaissance of circular bioeconomy can be conceived. And yes, we're at a tipping point for economic transformation. There's still a lot more research to do in this area! I've been especially

interested in the connections between circular bioeconomy, the plant industry, manufacturing, renewable energy and housing and how these could synergistically work together in policy. Too much

change too quickly? An oasis in the desert? Read on...

Key priority policy reform areas for circular bioeconomy

- climate change acceleration

- science

- Universities

- more CSIRO climate scientists

- AI, used as a research tool

- policy

- adaptation and resilience

- fossil Carbon export tax (Prof Ross Garnaut and Prof Rod Sims model)

- fracking ban

- circular bioeconomy (see below)

- renewable energy (see below)

- water

- Redox Flow Desalination (RFD) (at model stage)

- greater groundwater protections

- stormwater managed sponge cities with Biochar pavements, roads and water filtration

- water tank subsidies

- Permaculture bioregional planning

- prescribed burns for bushfire management using First Nations 'cool burning' techniques

- emergency services

- more funding for logistics (how long is a piece of string?)

- mobile command centres eg. Sesame Solar

- circular bioeconomy

- plant industry

- regenerative growing systems

- agriculture, forestry, agroforestry and horticulture

- industrial hemp

- bamboo

- microalgae

- macroalgae/seaweed farming

- aquaculture

- fishing

- See 'sitemap' for "Plant Civilization for sustainable adaptation to climate change" blog (11/24/2024)

- National Pyrolysis Strategy

- ANZBIG funding ($11 million would be handy!)

- National Carbon Removal Marketplace platform

- Carbon Dioxide Removal (CDR) credits to replace ACCUs

- Biochar and it's applications

- kiln and stove technologies startup capital

- advanced Carbon materials

- biomass

- Biochar

- plastic upcycling/Pyrolysis

- more funding for Universities

- greater international collaboration eg. China, US, EU, Japan, the rest of the world

- See 'sitemap' for "Key technologies for biochar circular bioeconomy" blog (5/19/2025)

- manufacturing

- 'Future Made in Australia' planning and action

- biotechnology (with close collaboration with the 'Plant industry' area)

- renewable energy

- transition from linear energy systems to circular energy systems (try an AI search...)

- linear energy systems eg. fossil fuel

- circular energy systems eg. main grid, community grids, household scales

- biomass + big batteries for dispatchable power, grid firming and grid reliability

- biomass to bioelectricity, ?heat and biochar

- Redox Flow Desalination (RFD) (at model stage)

- Biochar eg.bamboo to Carbon based solid state batteries and supercapacitors (blue sky)

- Biochar to Carbon based perovskite solar Photo Voltaic cells->panels (still at prototype stage)

- electrified Military + Civilian logistics R&D with subsidies where needed

- close collaboration with Oz battery industry eg. 'Queensland battery industry strategy'

- potential new ventures with a rebooted automotive industry

- free solar PVs and community batteries for remote First Nations communities

- mining

- critical minerals eg. Cu, Al, Fe, Na, Mn, Si, Ga et al

- Steam activated bamboo biochar-Mn-MOF for soil remediation of heavy metals etc. contamination and

water filtration of contaminated water

- efficient water use with better groundwater protections

- ban of As in gold/other mines

- fracking ban

- housing for homeless

- hemp(char)crete ecovillages

- apprenticeships for homeless people to build them for themselves

- linked in to the Global Ecovillage Network (ecovillage.org)

- Permaculture design principles

- close collaboration with the building industry

- close collaboration with the hemp industry clustered in the 'Plant industry' area

- close collaboration with the 'Renewable energy' area

That's all for now!

Wed

30

Jul

2025

Artificial shortages of a fake transition fuel - an opportunity for biomass and electrification

The problem

Here's an example of breaking down a research problem into it's parts and generating some learning issues to test hypotheses and maybe build Australia's renewable energy system... though I have

to admit, it's a loaded 🎲 which wouldn't be unusual for the energy industry!!

Here it is:

Natural Gas (NG) exports are causing East Coast NG shortages.

NG is considered a 'Transition fuel' by the NG industry and any journalist, lobbyist and politician that repeats their marketing propaganda.

There could be an opportunity for adopting 'Carbon neutral' biomass fuels and 'Carbon negative' stoves such as Top-Lit UpDraft (TLUD) stoves that pyrolyse the biomass fuels eg. Wood pellets, into

Biochar to meet household cooking and water pasteurization/boiling demand to replace NG stovetops.

NG peakers are still used on the grid in some places.

'Carbon negative' bioelectricity has not yet replaced NG peakers.

Many hot water systems still use NG that could be replaced with electric heat pumps.

NG Corporations are paying minimal tax.

A fossil Carbon export tax could be on the table to raise money for various policies.

A circular bioeconomy could be goalposts for a more resilient and sustainable future.

The plant industry feeding biotechnology applications and industry is key to a bioeconomy.

Data points/Keywords

- natural gas (NG)

- NG exports

- NG East Coast shortages

- NG marketing propaganda

- transition fuels

- 'Carbon neutral' biomass fuels

- wood pellets

- 'Carbon negative' stoves

- TLUDs

- biochar

- cooking and water pasteurization/boiling demand

- NG peakers

- 'Carbon negative' bioelectricity

- electric heat pumps

- fossil C export tax

- circular bioeconomy

- plant industry

- biotechnology

Hypotheses

1. NG exports can be diverted to a NG domestic National Reserve to avoid NG shortages in the future

2. NG is a fake or false transition fuel and doesn't meet adopted criteria

3. Biomass can be converted to Biochar in TLUD stoves which is 'Carbon negative'

4. Biomass fuel meets adopted circular bioeconomy criteria

5. Bioelectricity converting biomass to Biochar can replace NG peakers on the grid with AI load prediction since it can take some time eg. 1 hour, to fire up a bioelectricity kiln to full

capacity

6. There could be an opportunity for electric heat pumps to replace NG hot water systems.

7. Affordable heat pumps could be manufactured in Oz with Gov subsidies

8. A fossil C export tax could fund manufacturing of biotechnology for a circular bioeconomy

Learning issues

- What are the criteria of a transition fuel?

- Does NG meet the criteria?

- Does biomass meet the criteria as a transition fuel or as a circular bioeconomy fuel, the endgame of a transition, and therefore not a transition fuel?

- Would a NG National Reserve meet East Coast/National demand and would NG Corporations cooperate? Eg., could the Gov legally prevent some NG exports and instead lock it in for domestic

consumption? Alternatively, would a fossil C export tax disincentivise fossil exports, to a degree, and ensure domestic NG demand is met?

- Are biomass to Biochar technologies 'Carbon negative'? Eg. If it produces Biochar, is that 'Carbon negative'?

- Will we ever run out of biomass fuel in Australia? Eg., will we ever run out of wood, rice husk or sorghum pellets etc.?

- What is the current uptake and future predicted uptake of NG, electric and biomass stoves?

- Can TLUDs meet the demand of stoves to replace NG?

- If not, could there affordable electric stovetops manufactured in Oz which the Gov could subsidise in their 'Future Made in Australia' policy?

- What TLUDs can be safely used indoors, eg.Fabstove and outdoors, eg. Navigator 'Awesome' V2, Navigator 'Versatile', Navigator 'Backup' V2 etc.?

- Can NG peakers be replaced with 'Carbon negative' bioelectricity that produces biochar as a by-product?

- Are there affordable electric heat pumps manufactured in Oz?

- If not, is this something the Gov could subsidise in their 'Future Made in Australia' policy?

- what is a circular bioeconomy?

- what manufacturing could build a circular bioeconomy?

- could a fossil Carbon export tax subsidise manufacturing of biotechnology for a circular bioeconomy?

- what could be the main biotechnology applications and industry for a circular bioeconomy?

Also, just one more question for now for an AI chatbot eg. Perplexity.ai

"can problem based learning logic be applied to LLMs for research"

- it came up with some great mapping for PBL onto the LLM to 'keep the chatbot honest'!

- but, in saying that, the old medical school PBL algorithm pioneered by Dr Ted Cleary, published in the "Fact check this for a Biochar materials revolution" blog (18/7/25) in the blogs section

on my website, can be used very effectively, especially in group learning environments

Thu

24

Jul

2025

TLUD action!

Maybe the days of top down visionaries providing an ethical compass for Civilisation are nearing an end with bottom up consumerism of just about any new digital technology being the main driving force of human progress. Yes, there were and still are tech visionaries (eg. Ada Lovelace, Sir Tim Berners-Lee, Linus Torvalds, Elon Musk, Aravind Srinivas and many more) driving this digital revolution but consumers are now more or less in control with feedback pushing new boundaries of R&D. Digital culture driven by the Internet, software, social media, streaming platforms, smartphones, AI and more is now the main vehicle for change. Grassroots DIY culture is shifting the power balance from Corporate control of consumer 'digital' or 'material' goods production, distribution and marketing back to people. Appropriate survival culture is the future for most people on the Planet whether anyone likes it or not, 'digital' AND 'material'. We cannot escape our 'material' existence that is driving climate change acceleration - not even AGIs that may eventually be built will still rely on vast amounts of compute power and 'material' energy and I believe it's doubtful though not impossible that these AGIs will have an ethical compass for Civilisation. Dogma, fact or truth? What is real and what is illusion? AI is not very good at writing about personal experience. There are still jobs for writers. The word is not dead yet and probably never will be. Which brings me to TLUDs...these guys are 'real' and perfect for a digital detox...

Top-Lit UpDraft (TLUD) technology is cornerstone 'material' and 'Carbon negative' appropriate survival culture, pioneered by Dr TLUD and his predecessors, Dr. Sai Bhaskar Reddy Nakka

(who coined 'Biocharculture') and many others in more recent years including me. Consume your own DIY TLUDs for self-empowerment. Biochar, the 'material' 'Carbon negative' byproduct

of TLUD stoves, is the future material of dreams with many functions. Air filtration, water filtration, treatment of sewage, growing systems, building materials, EMR shielding and even batteries

can be built 'Carbon negative' with Biochar.

The Navigator 'Awesome' V2 TLUD (on the 'Bush Survival System' page) for 'Institutional' cooking and water pasteurization and the smaller Navigator 'Versatile' TLUD (see web page - still under

testing) for cooking and water pasteurization with greater mobility than the 'Awesome' are at the cutting edge of my TLUD research, design and development. 5" stainless chimney flue, in my

opinion with extensive design and field testing experience, is key with the Navigator mainframe primary and secondary air slot system which can be grinded and customized for the next generation

of unpowered and cost effective cooking and WASH biomass fuelled stoves. Both models are still under testing and I will post results when they are informative. Almost every use case scenario has

been covered with these two designs, other than medium to large scale biochar production which could be done and to a degree is being done with TLUDs too.

The modularity feature of TLUDs should be considered too as multiple units can be run in parallel which scales nicely to 'fill the gaps' between increasingly larger TLUD designs for most use

cases of Biochar volumes required and cogeneration utility.

Cogeneration is what attracted me to smaller TLUDs, after building many larger flame cap Biochar kilns, for getting the biggest 'bang for buck' from biomass fuel. Biomass pellets from waste I

believe are the future for urban environments or more remotely, DIY pelletisation. As the TLUDs get bigger, cogen becomes more impractical and expensive but not out of the question.

The TLUD revolution is making inroads into permanent global Carbon removal but will only be effective over the long term if fossil fuel alternatives, such as 'natural gas' are completely 'phased

out'. There is a long way to go in this space so I hope you enjoy the ride, like I have, if you choose to take it and are committed to achieving a 'Safe climate' once again knowing that you are

well prepared for most survival situations. What's your destination if you don't know the journey on the path? Carbon emissions are a scarab on time. Can we change the game?

Good luck!!

Permachar

Permachar